GOST 9567-75 st20 09g2s Subtilitas Ferri tube

Specification

GOST Latin pipe ferrea/USSR STATUS VEXILLUM

GOST 8731-87, inconsutilem calidum deformatum tibiae ferro

GOST 8732-78 - fistulae ferreae calido-deformatae inconsutiles, in diametro exteriore fabricatae, muri crassitudinis et longitudinis sunt.

EN GOST 8732-78 Seamless Hot-Deformed Steel tubes-Range

GOST 8733-74 inconsutilem Frigidum et Calidum deformatum Ferro Tubes-Technical requisita

GOST 8734-75 Seamless Frigidum et Calidum deformatum Ferro tube-Range

GOST 9567-75 Subsecutio Ferri Tubes-Range

GOST 9940-72 Inconsutiles fistulae calidae deformes e corrosione resistente ferro factae

GOST 9941-72 Seamless frigus et calidum deforme tubus e corrosione resistens ferro

GOST 1060-76 Ferro inconsutilem frigidum deformatum fistulae ad aedificandas res technicas

GOST 5654-76 Ferro inconsutilem caldarium deformatum fistulae ad requisita fabricanda-technica

GOST 550-75 Ferro sesutilem fistulam pro petrolei processui et industria petrochemico ferro

GOST 14162-69 Tubae ferreae parvae magnitudines (capillares)

GOST 10192-62 Bimetallic inconsutiles tube-Range

GOST 21945-76 Inconsutilem fistulae calido-deformatae chalybeis admixtorum ex requisitis titanio-technicis factis

GOST 21729-76 Inconsutilem deformatum et calidum deformatum fistulae frigidae e fabrica carbonis et ferro commixti

Specification

| Standard | GOST 9567-75 |

| Gradus | ferro 10/20/35/45/20Cr/40X/30ХГСА |

| Delivery Condition | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) AS Rolled |

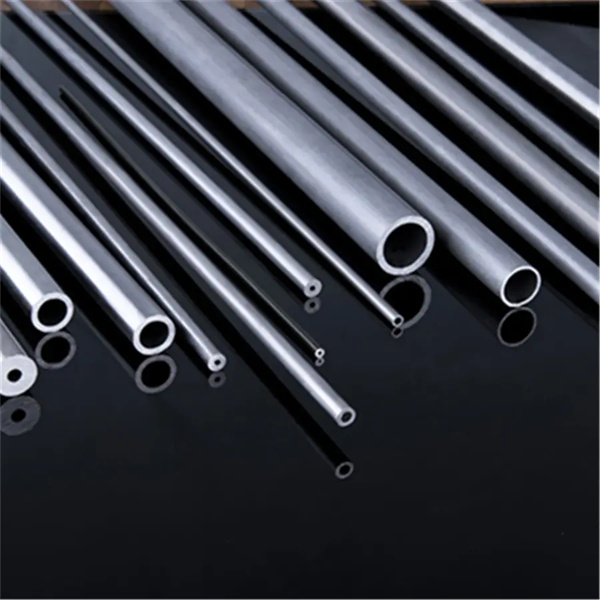

| Magnitudo | OD: 4 ad 219mm Crassitudo: 0.5-20mm; Longitudo: 3m,5.8,6 vel secundum requisita |

| perago | 1.Bare Tube (non coating) splendida et lenis 2.Galvanized superficies (Sliver/Yellow/Colorful) Zinc coating of 8-12um 3.Black PHOSPHATE |

| Applicationem | Hydraulic System;Car/bus;constructione vehiculum / Mechanica |

| Tempus adferendi | A.3 dies si hoc bonum est, stirps bona est. B. circiter XXX dies secundum quantitatem |

Chemical composition%)

| SteelGrade | C | Si | Mn | Cr | Ni | S | P | Cu |

| 10 | 0,07-0,14 | 0,17-0,37 | 0,35-0,65 | 0,15 | 0,3 | - | - | - |

| 20 | 0,17-0,24 | 0,17-0,37 | 0,35-0,65 | 0,25 | 0,25 | 0,03 | 0,025 | 0,3 |

| 35 | 0,32-0,40 | 0,17-0,37 | 0,50-0,80 | 0,25 | 0,3 | 0,04 | 0,035 | 0,3 |

| 45 | 0,42-0,45 | 0,17-0,37 | 0,50-0,80 | 0,25 | - | - | - | - |

| 40Х | 0,36-0,44 | 0,17-0,37 | 0,50-0,80 | 0,80-1,10 | 0,3 | 0,035 | 0,035 | 0,3 |

| 30ХГСА | 0,28-0,34 | 0,90-1,20 | 0,80-1,10 | 0,80-1,10 | 0,3 | 0,005 | 0,025 | - |

Mechanica res

| Steel Gradus | N/mm2 (min) | Vires cede, N/mm2 (min) | Prolongatio, %(min) |

| 10 | 343 | 206 | 24 |

| 20 | 412 | 245 | 21 |

| 35 | 510 | 294 | 17 |

| 45 | 589 | 323 | 14 |

| 40Х | 618 | - | 14 |

| 30ХГСА | 491 | - | 18 |

Applicationem

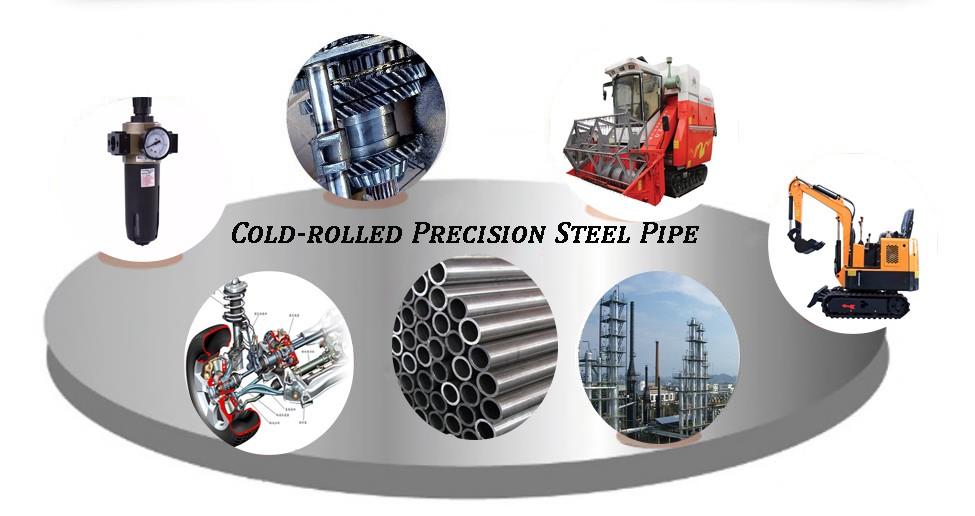

1.For Vehiculum (Automotiva, motivum, constructio machinarum sicut sentinam concretam et alii)

A. Power agmine ratio:

• Fuel fulcra • Fuel lineae • communes clausurae diesel lineae • Piston- rumpit • SCR & EGR .

• fistulae rigidae • tibiae oil- & aquarum refrigerationis

B. fluidi systemata pertractatio

• Tube comitia • Tubus aer-conditionalis • Tibiae actuator Clutch C. Coegi et ratio gubernandi • Ingrain Gear Pipes •

Power-Steering Feed-Pipes

D. systema hydraulicum

• Hydraulica et Pneumatica Pressurae Lineae • caerimoniae hydraulicae • Tubingae hydraulicae

E. Alii exempli gratia

• Axes anteriores • Sol-a

2. Mechanica et ipsum usus

• Mechanicus Processing and parts • Metal processing • Calor Exchange • Gas Cylinders

Sub mari et marino • Aerospace • Visentis Potestas Equipment • Energy and Power Generation • Gerentes, etc.

Alius usus ad singula sicut per clientium requisita

qualitas certitudine

1. stricto iuxta regulam.

2. Sample: Sample gratis test.

3. Expertus: Sal imbre test/test tensile / Eddy current / Chemical compositio test secundum clientium petitionem

4. Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification