Qualitas recognitionis pro Hot SUMMERGO Galvanized Ferro Pipe / Gi Pre Galvanized Ferro Pipe / inconsutilem Pipe

Nostras utilitates vis laboris, consilio et stili manipulus, technica coetus, QC cantavit et vis laboris obtinuit.Nunc tenemus strictam bonam qualitatem tractandi rationes ad singulas processus.Etiam omnes nostri opifices in re typographica experiuntur pro Qualitate Inspectionis pro Hot SUMMERGO Galvanized Ferro Pipe / Gi Pre Galvanized Ferro Pipe/Seamless Pipe, omnes emptores et pals suscipimus ut contact nos pro mutuis beneficiis additis.Spem facere additis negotiis incepti una vobiscum.

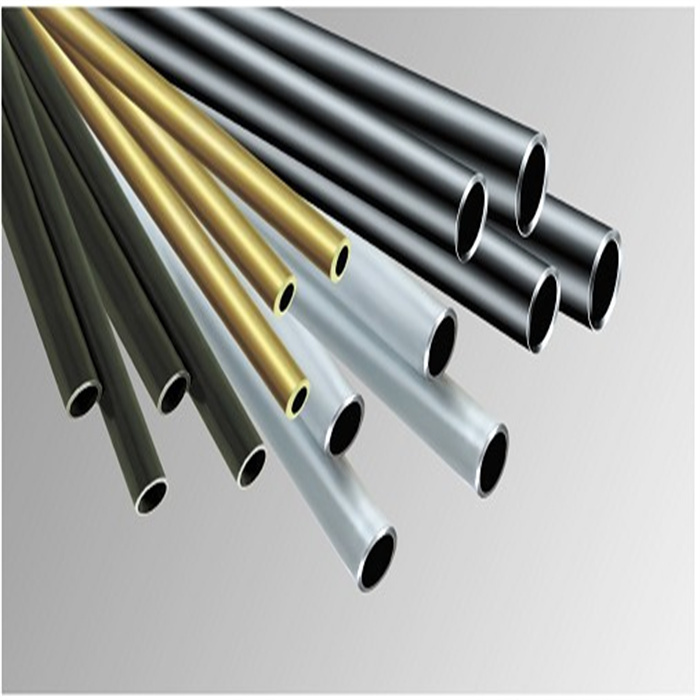

Nostras utilitates vis laboris, consilio et stili manipulus, technica coetus, QC cantavit et vis laboris obtinuit.Nunc tenemus strictam bonam qualitatem tractandi rationes ad singulas processus.Etiam omnes nostri operarii in re typographica periti suntSina Steel Pipe et Galvanized Pipe, Si quid productum mercedis exigis, fac liberum te nobis contingere.Certus es nos tuam inquisitionem vel postulationem promptam operam daturum esse, qualitatem rerum, pretia potiores et oneraria vilia.Gratum est sincere amicos toto orbe terrarum vocare vel visitare, ut de cooperatione pro meliore futuro collocentur!

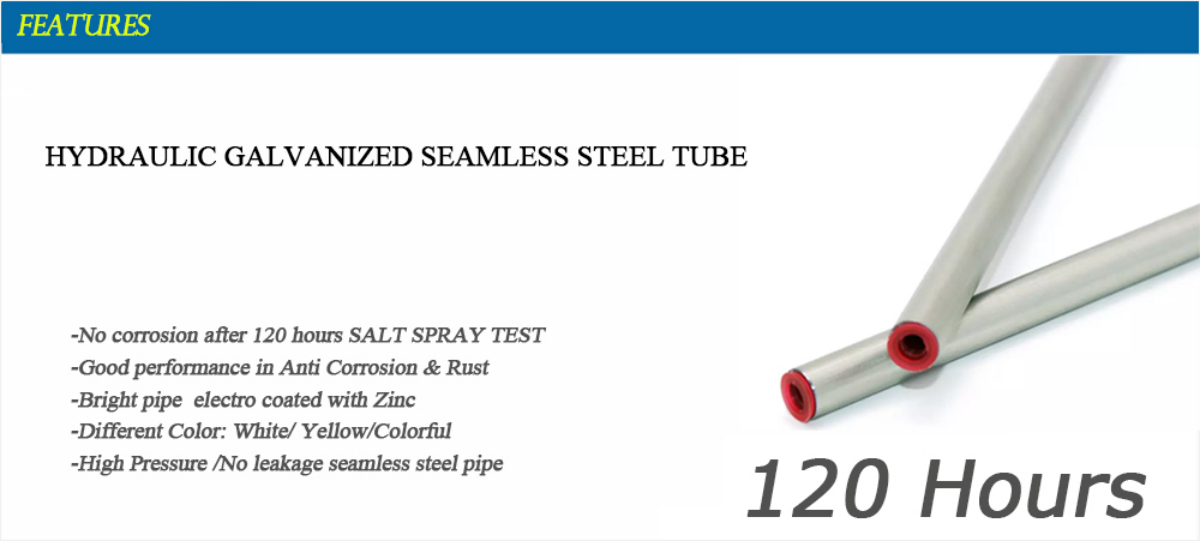

Features

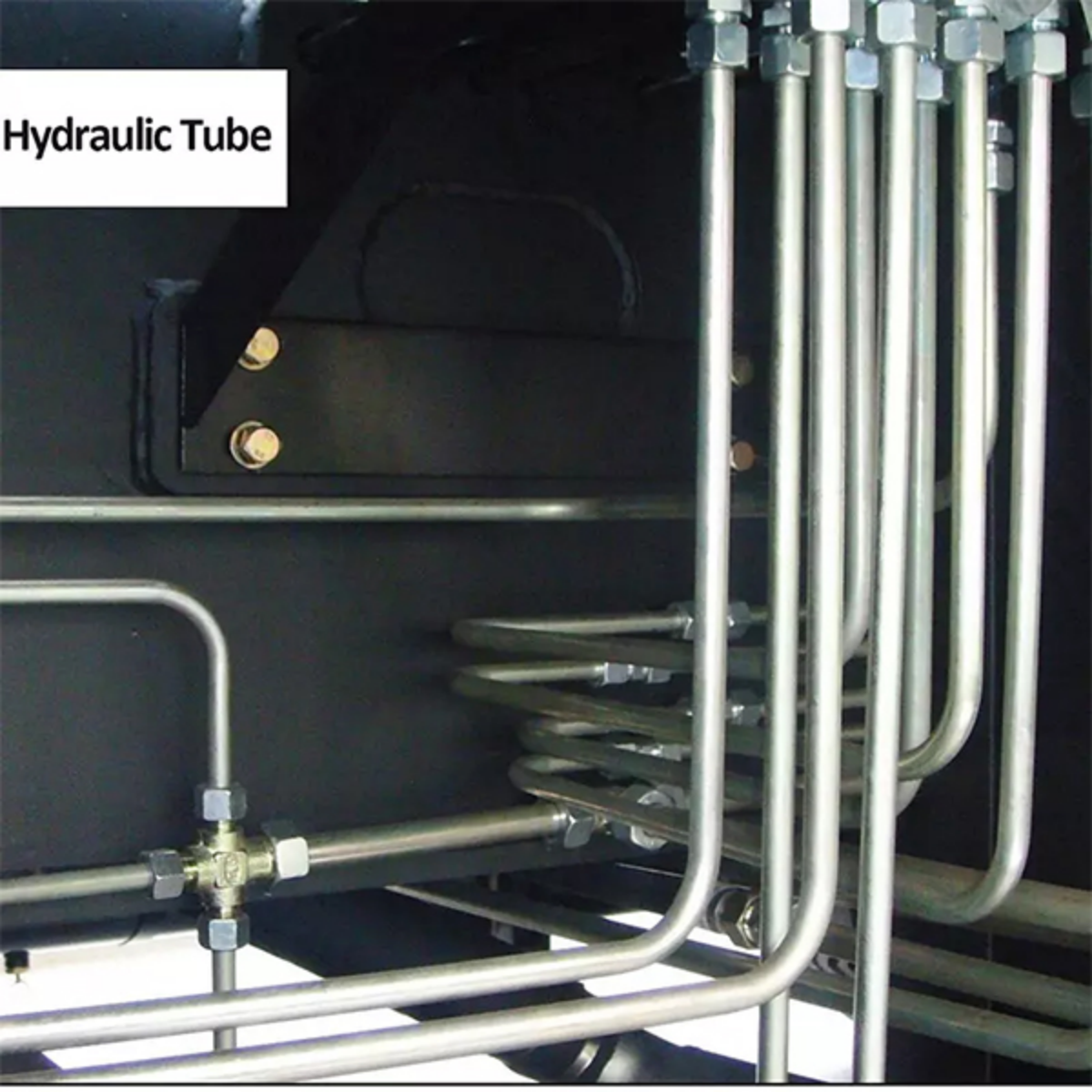

LAT/DIN Princeps praecisionem Galvanized Ferro Tube inclusam producit DIN 2391-C et EN10305-4.In systematis hydraulicis, machinae instrumentis, autocinetis, navibus, machinarum et vehiculis constructis, in usu est.Tubus hydraulicus galvanizatus inconsutilem chalybem magna subtilitate habet multas utilitates: nulla corrosio post 120 horas SAL RAMO TESTO;Bonus effectus in Anti Corrosion & Rust;Fistula electrici nitida cum zinco obducta;Color diversus: Albus / Flavus / LAETUS;Princeps Pressura / Nulla lacus seamless tibiam ferro.

Specification

| Standard | DIN2391 DIN1630 EN10305 DIN2445 JIS SAE J524 |

| Gradus | ST35/E235 ST37.4 ST45/E255 ST52/E355 |

| Delivery Condition | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) |

| Magnitudo | OD:4 ad 219mm Crassitudo 0.5-35mm, Longitudo: 3m,5.8,6 vel secundum exigentias |

| perago | Superficies Galvanized (Sliver/Yellow/Colorful) Zinc coating of 8-12um |

| Applicationem | Hydraulic System;Car/bus;constructione vehiculum |

| Tempus adferendi | A.3 dies si hoc bonum est copia bona.B.De XXX diebus secundum quantitatem |

| HYDRAULIC PRECSIO FERRUM TUBES IN STOCK | ||||||||||

| OD | Crassitudo (mm) | |||||||||

| mm | ||||||||||

| 4 | 4*1 | |||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | |||||||

| 8 | 8*1 | 8*1.5 | 8*2 | |||||||

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 | ||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 | |||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | |||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 | ||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 | ||

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 | ||

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 | |

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 | |

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 | |

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 | |

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 | 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 | |

| 34 | 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |

| 35 | 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | ||

| 40 | 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||

| 42 | 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||

| 45 | 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||

| 46 | 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||

| 48 | 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||

| 50 | 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||

| 54 | 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||

| 60 | 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | |||

| 65 | 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 | ||||

| 75 | 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 | |||||

| 76 | 76*4 | 76*4.5 | 76*5 | 76*6 | ||||||

| 89 | 89*6 | |||||||||

| Nota: Possemus alias magnitudinum magnitudines producere sicut postulationes tuas.Superficies Treatment: Bright, Galvanized, Phosphating etc. | ||||||||||

Chemical compositione

| Steel Gradus | C | Si | Mn | P | S | Al | |

| Nomen | Nec. | max | max | max | max | max | max |

| E215 | 1.0212 | 0.1 | 0.05 | 0.7 | 0.024 | 0.014 | 0.024 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.2 | 0.024 | 0.014 | - |

| E355 | 1.058 | 0.22 | 0.55 | 1.6 | 0.024 | 0.014 | - |

| ST35 | 1.0308 | 0.17 | 0.35 | 0.4(min) | 0.024 | 0.024 | - |

| ST45 | 1.0408 | 0.21 | 0.35 | 0.4(min) | 0.024 | 0.024 | - |

| ST52 | 1.058 | 0.22 | 0.55 | 1.6 | 0.024 | 0.024 | - |

Mechanica proprietatibus

| Steel Gradus | Fortitudo cede (Mpa) | Distrahens fortitudo (Mpa) | Prolongatio% | |

| Nomen | Nec. | ReH (min) | Rm(min) | A(min) |

| E215 | 1.0212 | 215 | 290 ad 430 | 30 |

| E235 | 1.0308 | 235 | 340 ad 480 | 25 |

| E355 | 1.058 | 355 | 490 ad 630 | 22 |

| ST35 | 1.0308 | 235 | 340 ad 480 | 25 |

| ST45 | 1.0408 | 255 | 440 ad 570 | 21 |

| ST52 | 1.058 | 355 | 490 ad 630 | 22 |

tolerantia

| OD | Tolerantia licita | Special Tolerantia | ||

| GB/T3639 | DIN2391 | OD | WT | |

| 4mm-20mm | ±0.10mm | ±0.08mm | ±0.05mm | ±0.05mm |

| 20mm-30mm | ±0.10mm | ±0.08mm | ±0.08mm | ±0.08mm |

| 31mm-40mm | ±0.15mm | ±0.15mm | ±0.10mm | ±0.08mm |

| 41mm-60mm | ±0.20mm | ±0.20mm | ±0.15mm | ±0.15mm |

| 61mm-80mm | ±0.30mm | ±0.30mm | ±0.20mm | ±0.20mm |

| 81mm-120mm | ±0.45mm | ±0.45mm | ±0.30mm | ±0.30mm |

Partus conditio

| Designatio | Symbolum | Descriptio |

| Frigus complevit (difficile) | BK(+C) | Tubuli caloris curationem non subeunt secundum extremum frigidum formantem et sic deformatio magis resistentia |

| Frigus complevit (Soft) | BKW | Curatio caloris extremum sequitur frigus attractum deformatio limitata.Aptus processus ulterior permittit quendam gradum formandi frigoris (exempli deflexio, expansio) |

| (+LC) | ||

| Frigidus complevit et accentus, sublevetur | BKS(+SR) | Curatio caloris applicata est post extremum frigidum processum formantem.Subiectis congruis condicionibus processui, incrementa residua extollit quae involvit, dat et formare et machinere aliquo modo. |

| Annealed | GBK(+A) | Ultimum processus frigidum formans sequitur furnum in atmosphaera moderata. |

| Normalised | NBK(+N) | Ultimum frigus processus formandi sequitur furnum super punctum transmutationis superioris in atmosphaera temperata. |

qualitas certitudine

1. Strict secundum DIN2391/EN10305 vel alia signa.

2. Sample: Sample gratis test.

3. Expertus: Sal imbre test/test tensile / Eddy current / Chemical compositio test secundum clientium petitionem

4. Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

Applicationem

Constanter exercemus animum nostrum “Innovationis progressum afferentem, qualitatem prorsus subsistendi.Hot Dipped Zinc Coating 40*40mm En10255 Schedule 40 Frigidum Rolled Galvanized Chalybs Round tube Pipe/Gi Galvanized Seamless Square Steel Pipe for Scaffolding, sincerity and strength, always maintain proved superior quanlity, welcome to our factty for go to and instruction and small business.

Sinis Factory Galvanized Steel Square Tube et cavum Sectionis Tube, fructus nostri maxime exportantur in Asiam meridiem-orientalem Euro-Americam, et venditiones ad omnem patriam nostram.Et fretus excellenti qualitate, rationabili pretio, optimo servitio, bonas opiniones a clientibus transmarinis Comperto.Gratus es ut nos ad plura possibilitates et utilitates adiungas.Clientes, negotia societates et amicos ex omnibus partibus orbis terrarum suscipimus ut nos contact et mutua beneficia quaeramus cooperationem.