JIS3445 Stkm11A 12A 13A Auto Tube

Superbi sumus de satisfactio emptoris et amplitudinis acceptionis ob pertinacem studiorum excellentium qualitatem tam in productum quam in servitium pro JIS3445 Stkm11A 12A 13A Auto Tube, Insuper nosmetipsos de applicatione technicarum solutionum ac solutionum adoptandi recte docebimus. per viam congruam materiam eligere.

Summus superbi satisfactio emptoris et late acceptationis ob pertinacem studiorum excellentium qualitatem tam in productum quam in servitiumstkm11a auto tube, Stkm11a Steel TubePonimus « honestum esse medicum ad continuum progressum et innovationem assequendum », uti dictum est.Experientiam nostram cum amicis domi et foris communicare vellemus, modo maiorem placentam cum communibus laboribus creandi.Plures experti sumus R & D personas et ordines OEM suscipimus.

Features

Gradus materialis:

STKM 11A 12A 12B 12C 13A 13B 13C 14A 14B 14C 15A 15C etc.

Superficiem treatment:

1.Bared

2.Black pingitur (varnish coating)

3.Galvanized

4.Oiled

5. Secundum clientes.

JIS G3445 Praecisio fistulae chalybeae maxime adhibentur in partibus machinis automobile et praecisione carros et cylindrici.pressionis utendi, ac etiam ad transportandum vaporem, aquam, fistulam gasi lineas.

Chemical compositione

| Gradus | Designatio | Unitas (%) | ||||||

| C | Si | Mn | P | S | Nb vel V * | |||

| Gradus 11 | A | STKM 11A | 0.12 max. | 0.35 max. | 0.60 max. | 0.040 max. | 0.040 max. | - |

| Gradus 12 | A | STKM 12A | 0.20 max. | 0.35 max. | 0.6 max. | 0.04 max. | 0.04 max. | |

| B | STKM 12B | |||||||

| C | STKM 12C | |||||||

| Gradus 13 | A | STKM 13A | 0.25 max. | 0.35 max. | 0.30~0.90 | 0.040 max. | 0.040 max. | - |

| B | STKM 13B | |||||||

| C | STKM 13C | |||||||

| Gradus 14 | A | STKM 14A | 0.30 max. | 0.35 max. | 0.30~1.00 | 0.040 max. | 0.040 max. | - |

| B | STKM 14B | |||||||

| C | STKM 14C | |||||||

| Gradus 15 | A | STKM 15A | 0.25~0.35 | 0.35 max. | 0.30~1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 15C | |||||||

| Gradus 16 | A | STKM 16A | 0.35~0.45 | 0.40 max. | 0.40~1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 16C | |||||||

| Gradus 17 | A | STKM 17A | 0.45~0.55 | 0.40 max. | 0.40~1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 17C | |||||||

| Gradus 18 | A | STKM 18A | 0.18 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| B | STKM 18B | |||||||

| C | STKM 18C | |||||||

| Gradus 19 | A | STKM 19A | 0.25 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| C | STKM 19C | |||||||

| Gradus 20 | A | STKM 20A | 0.25 max. | 0.55 max. | 1.60 max. | 0.040 max. | 0.040 max. | 0.15 max |

Mechanica proprietatibus

| Steel Gradus | Fortitudo cede (Mpa) | Distrahens fortitudo (Mpa) | Prolongatio% | |

| Nomen | Nec. | ReH (min) | Rm(min) | A(min) |

| STKM 11A |

| _ | 290 | 35 |

| STKM 12A |

| 175 | 340 | 35 |

| STKM 12B |

| 275 | 390 | 25 |

| STKM 12C |

| 355 | 4700 | 20 |

| STKM13A |

| 215 | 370 | 30 |

| STKM 11B |

| 305 | 440 | 20 |

| STKM11C |

| 380 | 510 | 15 |

tolerantia

| MENSURA | Tolerantia licita | Special Tolerantia | ||

| OD | WT | OD | WT | |

| 4mm-20mm | ±0.25mm | <3mm±0.3mm;

≥3mm ±10%

| ±0.05mm | ±0.05mm |

| 20mm-30mm | ±0.25mm | ±0.08mm | ±0.08mm | |

| 31mm-40mm | ±0.25mm | ±0.10mm | ±0.08mm | |

| 41mm-49mm | ±0.25mm | ±0.15mm | ±0.15mm | |

| 50mm-80mm | ±0.5% | ±0.20mm | ±0.20mm | |

| 81mm-120mm | ±0.5% | ±0.30mm | ±0.30mm | |

Partus conditio

| Designatio | Symbolum | Descriptio |

| Frigus complevit (difficile) | BK(+C) | Tubuli caloris curationem non subeunt secundum extremum frigidum formantem et sic deformatio magis resistentia |

| Frigus complevit (Soft) | BKW | Curatio caloris extremum sequitur frigus attractum deformatio limitata.Aptus processus ulterior permittit quendam gradum formandi frigoris (exempli deflexio, expansio) |

| (+LC) | ||

| Frigidus complevit et accentus, sublevetur | BKS(+SR) | Curatio caloris applicata est post extremum frigidum processum formantem.Subiectis congruis condicionibus processui, incrementa residua extollit quae involvit, dat et formare et machinere aliquo modo. |

| Annealed | GBK(+A) | Ultimum processus frigidum formans sequitur furnum in atmosphaera moderata. |

| Normalised | NBK(+N) | Ultimum frigus processus formandi sequitur furnum super punctum transmutationis superioris in atmosphaera temperata. |

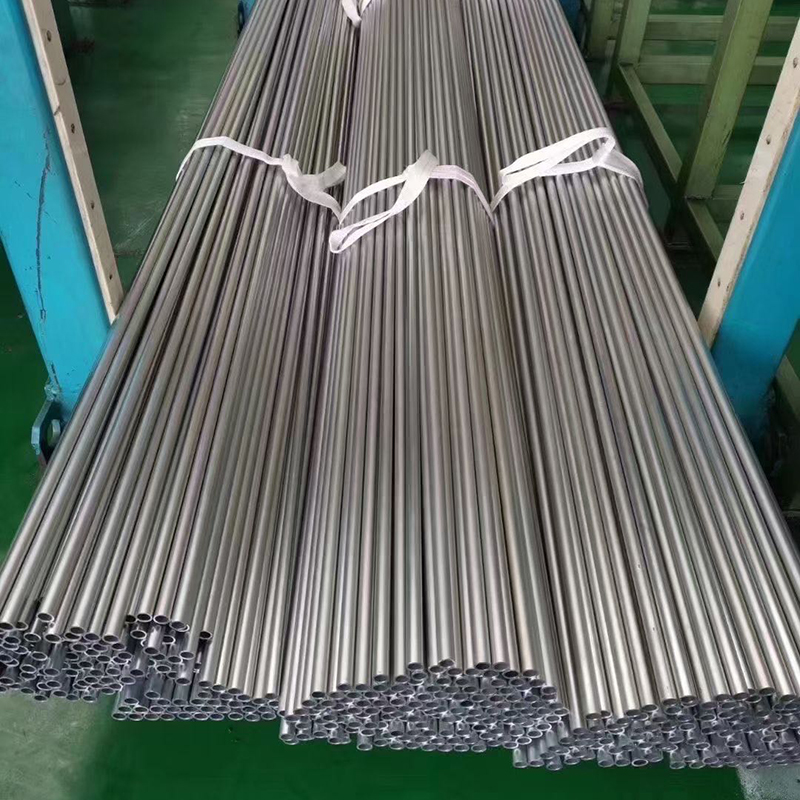

| Princeps Precision Ferro Tubes in Stock | ||||||||||

| OD | Crassitudo (mm) | |||||||||

| mm | ||||||||||

| 4 | 4*1 | |||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | |||||||

| 8 | 8*1 | 8*1.5 | 8*2 | |||||||

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 | ||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 | |||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | |||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 | ||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 | ||

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 | ||

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 | |

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 | |

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 | |

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 | |

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 | 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 | |

| 34 | 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |

| 35 | 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | ||

| 40 | 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||

| 42 | 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||

| 45 | 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||

| 46 | 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||

| 48 | 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||

| 50 | 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||

| 54 | 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||

| 60 | 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | |||

| 65 | 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 | ||||

| 75 | 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 | |||||

| 76 | 76*4 | 76*4.5 | 76*5 | 76*6 | ||||||

| 89 | 89*6 | |||||||||

| Nota: Possemus alias magnitudinum magnitudines producere sicut postulationes tuas.Superficies Treatment: Bright, Galvanized, Phosphate etc. | ||||||||||

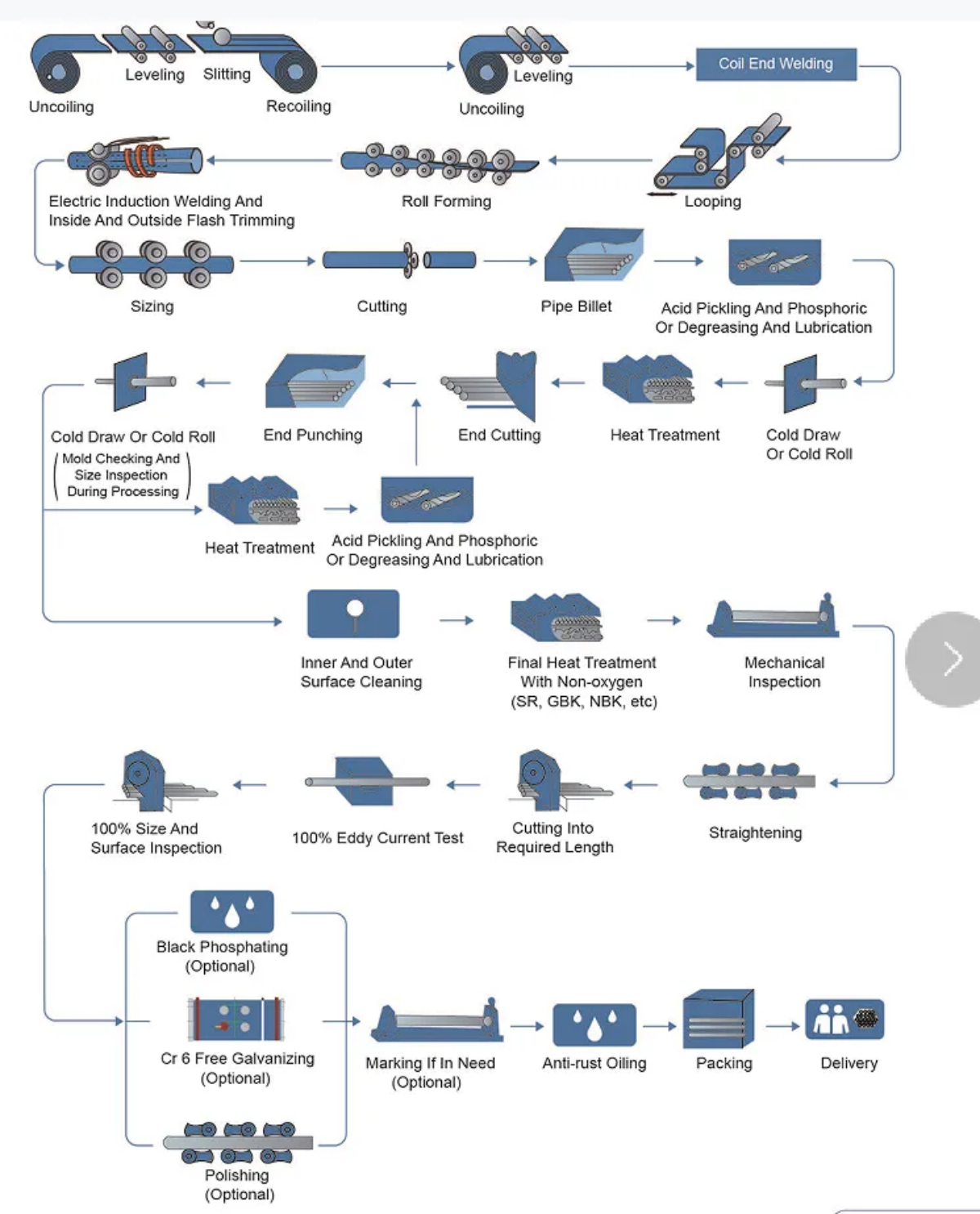

Processus fabricare

commoda

Confirma inspectionem productorum in unaquaque scaena productionis, instrumentis perfectis probatis instructum: probatio vena non perniciosa, alta pressionis resistentia, machina probatio, machina machinalis tensilis universalis, inclinatio adulatione, machina probatio, munditia analystor, elementum metallum analysr, etc. Conveniant proprietatibus mechanicis productorum, processus effectus test, validam cautionem pro idoneis products praebent.

qualitas certitudine

1. Strict iuxta JIS G3445 Latin vel alia signa.

2. Sample: Sample gratis test.

3. Expertus: Sal imbre test/test tensile / Eddy current / Chemical compositio test secundum clientium petitionem

4. Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

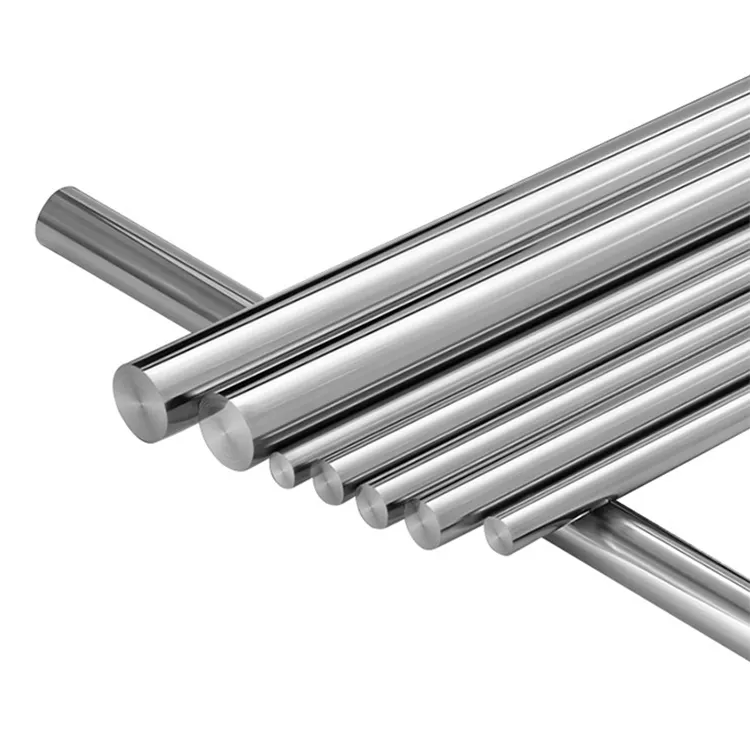

STKM11A gradus materialis in Iaponia est, maxime referens ad fistulas carbonii ad structuras mechanicas.

Admisce conpositio content:

C: 0.12% Si: 0.35% Mn: 0.60% P: 0.04% S: 0.04% 4. Mechanica proprietates:

Duritia et duritia fistulae ferreae STKM11a sunt 950HV, et fortitudo distrahens per suam fortitudinem determinatur σ B (MPa): ≥ 295 elongatio δ/%: longitudinalis ≥ 35, transversa ≥ 30 structuralis ferri attendere debet duritiem.STKM11 commune est chalybeum carbonis, et STKM11A est gradus chalybis ad fistulas carbonis in structuras mechanicas adhibitas.Gradus Iaponicae est correspondentes cum vexillo nationali Sinarum fistulam 10 # chalybem.

Superbi sumus de satisfactio emptoris et amplitudinis acceptionis ob pertinacem studiorum excellentium qualitatem tam in productum quam in servitium pro pretio citato pro JIS3445 Stkm11A 12A 13A Auto Tube, Insuper clientes de applicationibus technicis utendis recte docebimus. nostras solutiones et modum opportunas materias eligere.

Pretium citatum pro Sinis Seamless Ferro Pipe et Pipe Opportunus, "fidelem medicum esse constituimus ad continuam progressionem et innovationem" assequendam, ut dictum est.Experientiam nostram cum amicis domi et foris communicare vellemus, modo maiorem placentam cum communibus laboribus creandi.Plures experti sumus R & D personas et ordines OEM suscipimus.