Factory Customized Hot Rolled Cold Rolled cold drawn drawn Carbon Steel cava Seamless Steel tube Pipe

Satisfactio emptoris est prima scopus noster.Constantem gradum facimus professionalismi, qualitatis, credibilitatis et servitii pro Factory Customized Hot Rolled Cold Rolled Cold Drawn Carbon Steel Hollow Seamless Steel Tube Pipe, Negotium nostrum iam inseruit professionalem, creatrix et responsalis vis laboris ad emendandos emptores una cum multi- libens principium.

Satisfactio emptoris est prima scopus noster.Firmamus gradum professionalismi, qualitatem, fidem et servitium proSina Steel Pipe et Seamless Steel PipeGrata invisere societatem nostram, officinam et spectaculum nostrum ubi varias solutiones capillorum ostendit quae exspectationi tuae occurrent.Interim commodum est nostrum locum invisere, et baculus venditionum nostrarum optimam operam tibi tradere conabitur.Vide ut contact nos si vis plura indicia.Propositum est auxilium clientibus suis metis cognoscere.Magnos conatus sumus rem hanc vincere-vincere.

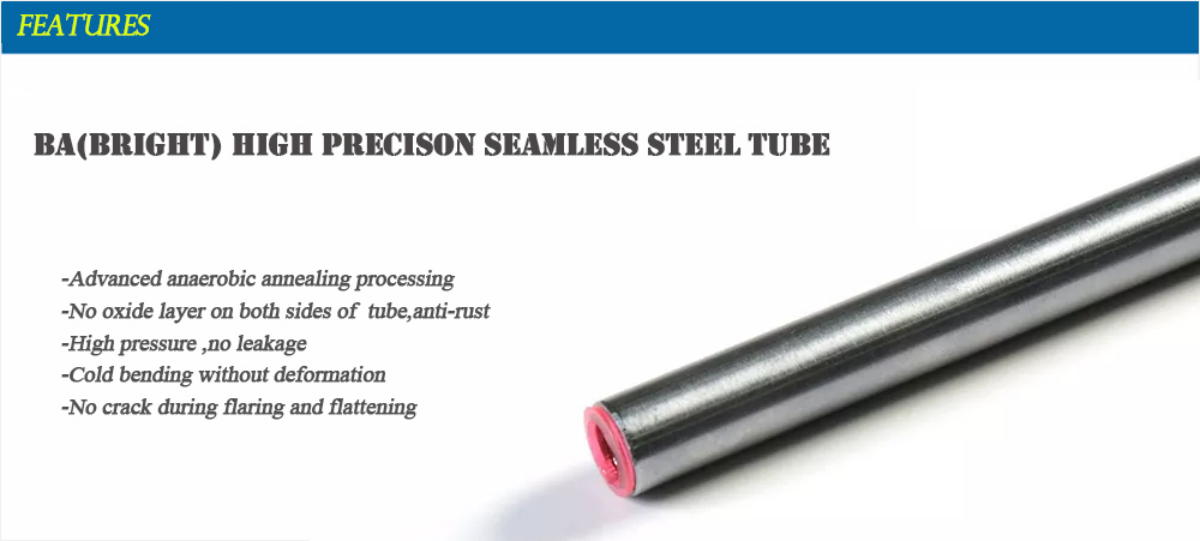

Features

Tubus potest curvare, flare et adulatione sine rima.Magnam praecisionem habet, super stratum oxydatum utrinque tubi.Ad varias deformationes et machinationes implicatas adhiberi potest.BA alta praecisio est inconsutilem ferri tubulum solere adhiberi ad cylindrum hydraulica, diesel, hydrau statio sentinae et systematis hydraulicum, quae tubus chalybeis in alta subtilitate et munditia requirunt.

Specification

| Standard | DIN2391 DIN1630 EN10305 DIN2445 JIS SAE J524 |

| Gradus | ST35/E235 ST37.4 ST45/E255 ST52/E355 |

| Delivery Condition | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) |

| Magnitudo | OD:4 ad 219mm Crassitudo 0.5-35mm, Longitudo: 3m,5.8,6 vel secundum exigentias |

| perago | Superficies Galvanized (Sliver/Yellow/Colorful) Zinc coating of 8-12um |

| Applicationem | Hydraulic System;Car/bus;constructione vehiculum |

| Tempus adferendi | A.3 dies si hoc bonum est copia bona.B.De XXX diebus secundum quantitatem |

| HYDRAULIC ACCURATIO FERRUM TUBES IN STOCK | ||||||||||

| OD | Crassitudo (mm) | |||||||||

| mm | ||||||||||

| 4 | 4*1 | |||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | |||||||

| 8 | 8*1 | 8*1.5 | 8*2 | |||||||

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 | ||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 | |||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | |||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 | ||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 | ||

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 | ||

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 | |

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 | |

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 | |

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 | |

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 | 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 | |

| 34 | 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |

| 35 | 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | ||

| 40 | 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||

| 42 | 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||

| 45 | 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||

| 46 | 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||

| 48 | 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||

| 50 | 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||

| 54 | 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||

| 60 | 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | |||

| 65 | 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 | ||||

| 75 | 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 | |||||

| 76 | 76*4 | 76*4.5 | 76*5 | 76*6 | ||||||

| 89 | 89*6 | |||||||||

| Nota: Possemus alias magnitudinum magnitudines producere sicut postulationes tuas. Superficies Treatment: Bright, Galvanized, Phosphated etc. | ||||||||||

Chemical compositione

| Steel Gradus | C | Si | Mn | P | S | Al | |

| Nomen | Nec. | max | max | max | max | max | max |

| E215 | 1.0212 | 0.1 | 0.05 | 0.7 | 0.024 | 0.014 | 0.024 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.2 | 0.024 | 0.014 | - |

| E355 | 1.058 | 0.22 | 0.55 | 1.6 | 0.024 | 0.014 | - |

| ST35 | 1.0308 | 0.17 | 0.35 | 0.4(min) | 0.024 | 0.024 | - |

| ST45 | 1.0408 | 0.21 | 0.35 | 0.4(min) | 0.024 | 0.024 | - |

| ST52 | 1.058 | 0.22 | 0.55 | 1.6 | 0.024 | 0.024 | - |

Mechanica proprietatibus

| Steel Gradus | Fortitudo cede (Mpa) | Distrahens fortitudo (Mpa) | Prolongatio% | |

| Nomen | Nec. | ReH (min) | Rm(min) | A(min) |

| E215 | 1.0212 | 215 | 290 ad 430 | 30 |

| E235 | 1.0308 | 235 | 340 ad 480 | 25 |

| E355 | 1.058 | 355 | 490 ad 630 | 22 |

| ST35 | 1.0308 | 235 | 340 ad 480 | 25 |

| ST45 | 1.0408 | 255 | 440 ad 570 | 21 |

| ST52 | 1.058 | 355 | 490 ad 630 | 22 |

tolerantia

| OD | Tolerantia licita | Special Tolerantia | ||

| GB/T3639 | DIN2391 | OD | WT | |

| 4mm-20mm | ±0.10mm | ±0.08mm | ±0.05mm | ±0.05mm |

| 20mm-30mm | ±0.10mm | ±0.08mm | ±0.08mm | ±0.08mm |

| 31mm-40mm | ±0.15mm | ±0.15mm | ±0.10mm | ±0.08mm |

| 41mm-60mm | ±0.20mm | ±0.20mm | ±0.15mm | ±0.15mm |

| 61mm-80mm | ±0.30mm | ±0.30mm | ±0.20mm | ±0.20mm |

| 81mm-120mm | ±0.45mm | ±0.45mm | ±0.30mm | ±0.30mm |

Partus conditio

| Designatio | Symbolum | Descriptio |

| Frigus complevit (difficile) | BK(+C) | Tubuli caloris curationem non subeunt secundum extremum frigidum formantem et sic deformatio magis resistentia |

| Frigus complevit (Soft) | BKW | Curatio caloris extremum sequitur frigus attractum deformatio limitata.Aptus processus ulterior permittit quendam gradum formandi frigoris (exempli. flexionis, expansionis) |

| (+LC) | ||

| Frigidus complevit et accentus, sublevetur | BKS(+SR) | Curatio caloris applicata est post extremum frigidum processum formantem.Subiectis congruis condicionibus processui, incrementa residua extollit quae involvit, dat et formare et machinere aliquo modo. |

| Annealed | GBK(+A) | Ultimum processus frigidum formans sequitur furnum in atmosphaera moderata. |

| Normalised | NBK(+N) | Ultimum frigus processus formandi sequitur furnum super punctum transmutationis superioris in atmosphaera temperata. |

qualitas certitudine

1. Strict secundum DIN2391/EN10305 vel alia signa.

2. Sample: Sample gratis test.

3. Expertus: Sal imbre test/test tensile / Eddy current / Chemical compositio test secundum clientium petitionem

4. Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

Applicationem

Satisfactio emptoris est prima scopus noster.Constantem gradum facimus professionalismi, qualitatis, credibilitatis et servitii pro Factory Customized Hot Rolled Cold Rolled Cold Drawn Carbon Steel Hollow Seamless Steel Tube Pipe, Negotium nostrum iam inseruit professionalem, creatrix et responsalis vis laboris ad emendandos emptores una cum multi- libens principium.

Factory customizedSina Steel Pipe et Seamless Steel PipeGrata invisere societatem nostram, officinam et spectaculum nostrum ubi varias solutiones capillorum ostendit quae exspectationi tuae occurrent.Interim commodum est nostrum locum invisere, et baculus venditionum nostrarum optimam operam tibi tradere conabitur.Vide ut contact nos si vis plura indicia.Propositum est auxilium clientibus suis metis cognoscere.Magnos conatus sumus rem hanc vincere-vincere.