LAT/DIN High Precision Galvanized Seamless Steel Tube

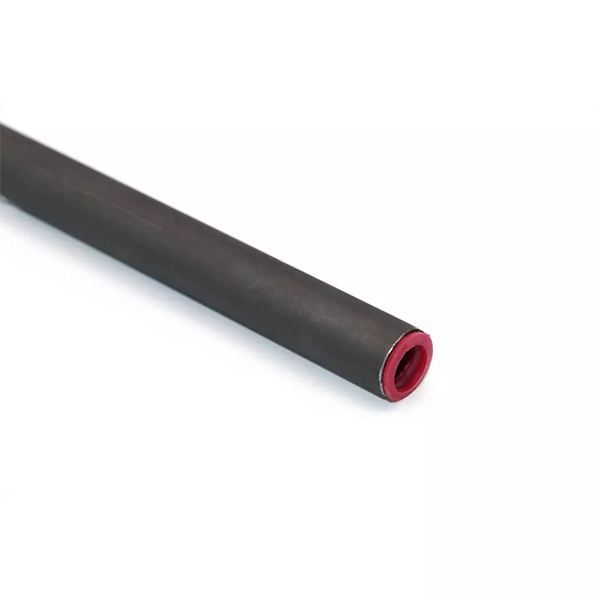

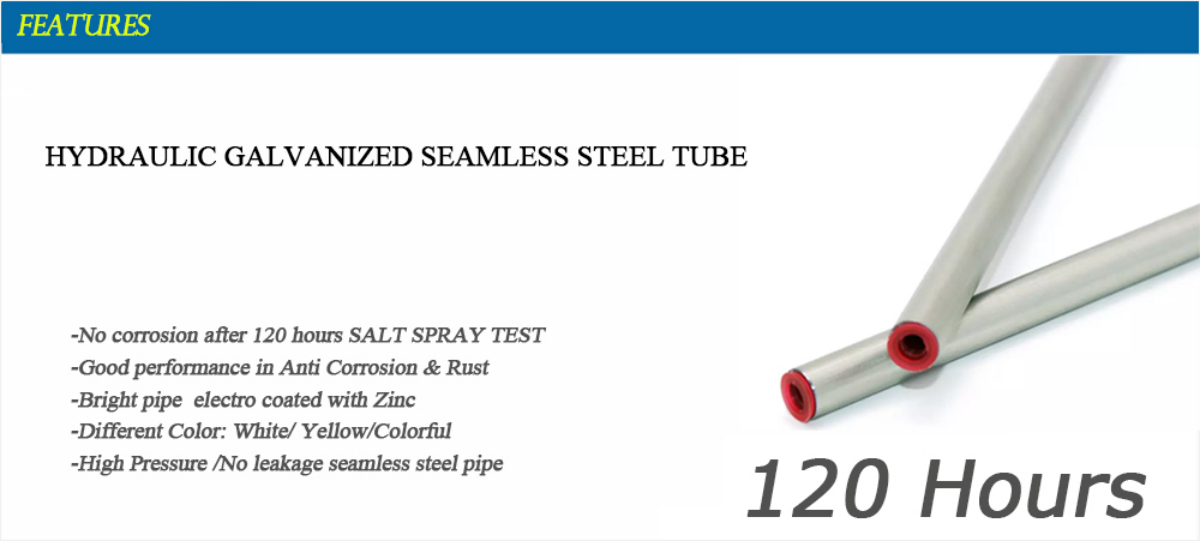

LAT/DIN Praecisione Galvanized Ferro Tubus Seamless prodit innixus DIN 2391-C et EN10305-4.In systematis hydraulicis, machinae instrumentis, autocinetis, navibus, machinarum et vehiculis constructis, in usu est.Tubus hydraulicus galvanizatus inconsutilem chalybem magna subtilitate habet multas utilitates: nulla corrosio post 120 horas SAL RAMO TESTA;Bonus effectus in Anti Corrosion & Rust;Fistula electrici nitida cum zinco obducta;Color diversus: Albus / Flavus / LAETUS;Princeps Pressura / Nulla lacus seamless tibiam ferro.

Specification

| Standard | DIN2391 DIN1630 EN10305 DIN2445 JIS SAE J524 |

| Gradus | ST35/E235 ST37.4 ST45/E255 ST52/E355 |

| Delivery Condition | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) |

| Magnitudo | OD:4 ad 219mm Crassitudo 0.5-35mm, Longitudo: 3m,5.8,6 vel secundum exigentias |

| perago | Superficies Galvanized (Sliver/Yellow/Colorful) Zinc coating of 8-12um |

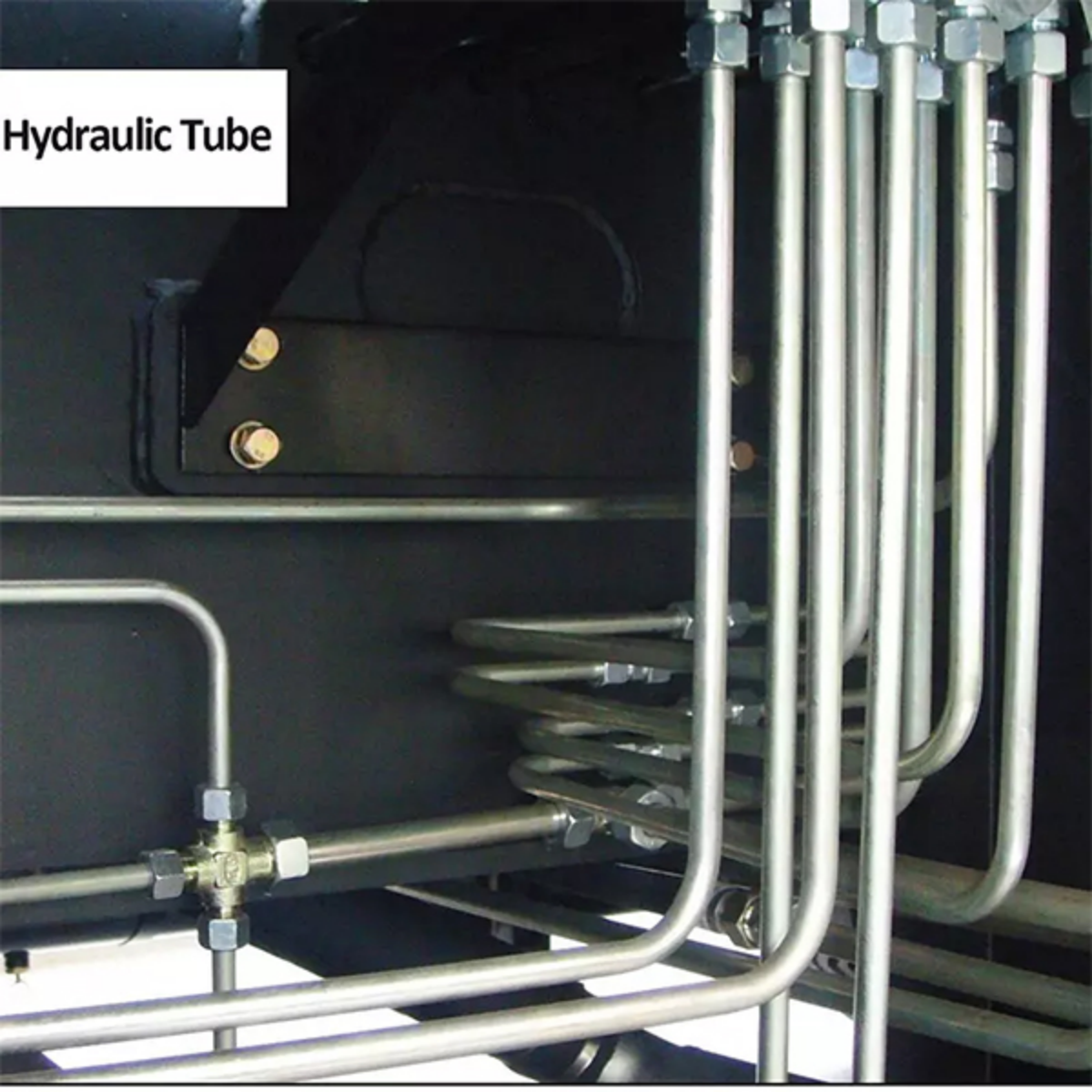

| Applicationem | Hydraulic System;Car/bus;constructione vehiculum |

| Tempus adferendi | A.3 dies si hoc bonum est, stirps bona est.B. circiter XXX dies secundum quantitatem |

| HYDRAULIC PRECSIO FERRUM TUBES IN STOCK | ||||||||||

| OD | Crassitudo (mm) | |||||||||

| mm | ||||||||||

| 4 | 4*1 | |||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | |||||||

| 8 | 8*1 | 8*1.5 | 8*2 | |||||||

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 | ||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 | |||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | |||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 | ||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 | ||

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 | ||

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 | |

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 | |

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 | |

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 | |

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 | 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 | |

| 34 | 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |

| 35 | 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | ||

| 40 | 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||

| 42 | 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||

| 45 | 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||

| 46 | 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||

| 48 | 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||

| 50 | 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||

| 54 | 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||

| 60 | 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | |||

| 65 | 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 | ||||

| 75 | 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 | |||||

| 76 | 76*4 | 76*4.5 | 76*5 | 76*6 | ||||||

| 89 | 89*6 | |||||||||

| Nota: Possemus alias magnitudinum magnitudines producere sicut postulationes tuas.Superficies Treatment: Bright, Galvanized, Phosphating etc. | ||||||||||

Chemical compositione

| Steel Gradus | C | Si | Mn | P | S | Al | |

| Nomen | Nec. | max | max | max | max | max | max |

| E215 | 1.0212 | 0.1 | 0.05 | 0.7 | 0.024 | 0.014 | 0.024 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.2 | 0.024 | 0.014 | - |

| E355 | 1.058 | 0.22 | 0.55 | 1.6 | 0.024 | 0.014 | - |

| ST35 | 1.0308 | 0.17 | 0.35 | 0.4(min) | 0.024 | 0.024 | - |

| ST45 | 1.0408 | 0.21 | 0.35 | 0.4(min) | 0.024 | 0.024 | - |

| ST52 | 1.058 | 0.22 | 0.55 | 1.6 | 0.024 | 0.024 | - |

Mechanica proprietatibus

| Steel Gradus | Fortitudo cede (Mpa) | Distrahens fortitudo (Mpa) | Prolongatio% | |

| Nomen | Nec. | ReH (min) | Rm(min) | A(min) |

| E215 | 1.0212 | 215 | 290 ad 430 | 30 |

| E235 | 1.0308 | 235 | 340 ad 480 | 25 |

| E355 | 1.058 | 355 | 490 ad 630 | 22 |

| ST35 | 1.0308 | 235 | 340 ad 480 | 25 |

| ST45 | 1.0408 | 255 | 440 ad 570 | 21 |

| ST52 | 1.058 | 355 | 490 ad 630 | 22 |

tolerantia

| OD | Tolerantia licita | Special Tolerantia | ||

| GB/T3639 | DIN2391 | OD | WT | |

| 4mm-20mm | ±0.10mm | ±0.08mm | ±0.05mm | ±0.05mm |

| 20mm-30mm | ±0.10mm | ±0.08mm | ±0.08mm | ±0.08mm |

| 31mm-40mm | ±0.15mm | ±0.15mm | ±0.10mm | ±0.08mm |

| 41mm-60mm | ±0.20mm | ±0.20mm | ±0.15mm | ±0.15mm |

| 61mm-80mm | ±0.30mm | ±0.30mm | ±0.20mm | ±0.20mm |

| 81mm-120mm | ±0.45mm | ±0.45mm | ±0.30mm | ±0.30mm |

Partus conditio

| Designatio | Symbolum | Descriptio |

| Frigus complevit (difficile) | BK(+C) | Tubuli caloris curationem non subeunt secundum extremum frigidum formantem et sic deformatio magis resistentia |

| Frigus complevit (Soft) | BKW | Curatio caloris extremum sequitur frigus attractum deformatio limitata.Aptus processus ulterior permittit quendam gradum formandi frigoris (exempli deflexio, expansio) |

| (+LC) | ||

| Frigidus complevit et accentus, sublevetur | BKS(+SR) | Curatio caloris applicata est post extremum frigidum processum formantem.Subiectis congruis condicionibus processui, incrementa residua extollit quae involvit, dat et formare et machinere aliquo modo. |

| Annealed | GBK(+A) | Ultimum processus frigidum formans sequitur furnum in atmosphaera moderata. |

| Normalised | NBK(+N) | Ultimum frigus processus formandi sequitur furnum super punctum transmutationis superioris in atmosphaera temperata. |

qualitas certitudine

1. Strict secundum DIN2391/EN10305 vel alia signa.

2. Sample: Sample gratis test.

3. Expertus: Sal imbre test/test tensile / Eddy current / Chemical compositio test secundum clientium petitionem

4. Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

Applicationem