LAT/DIN Cold Tractus Black Phosphated praecisione hydrau Steel Tube

Product Detail

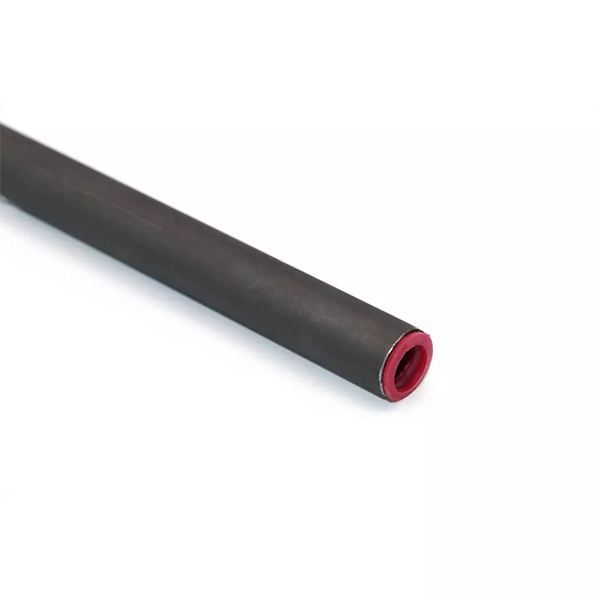

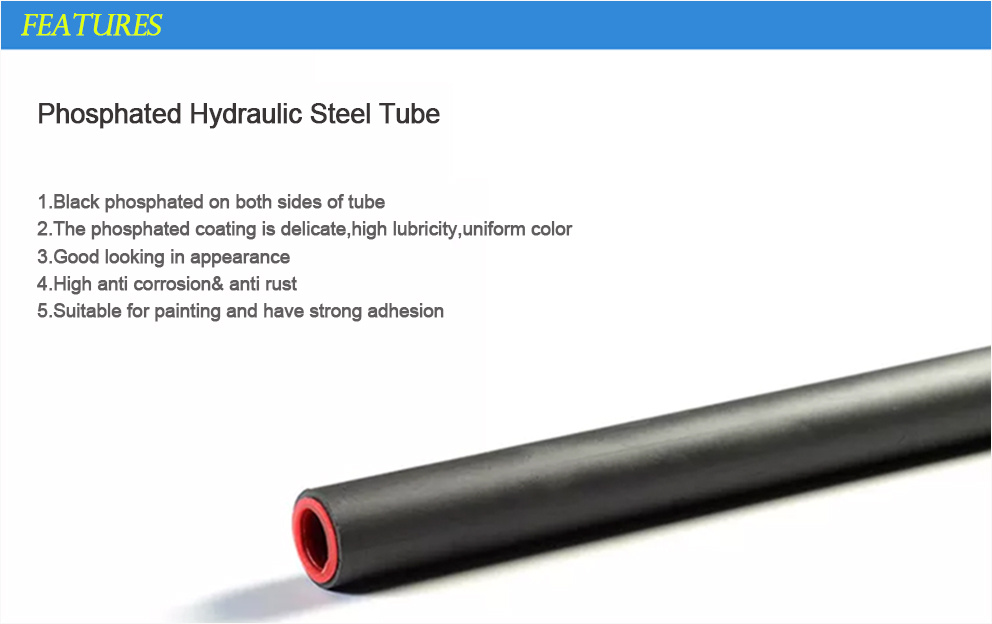

Tubus chalybs phosphatus hydrau- cus niger nascitur secundum DIN 2391-C vel En10305-4.Fistulae ex ferro nigro phosphatae hydraulicae fiunt e frigido ductae lucida tibiae ferreo ut subiectae.Et parietes interiores et exteriores fistularum phosphatantur cum solutione phosphating ad formandum velum tutelae phosphating nigrum.Aeruginem renitens oleum per micropora in phosphating pellicularum ad rubiginem praecavendam curationem hauriunt, et utrumque ad pulverem praecavendam curationem obtegunt.Praecipuae notae hydraulicae nigrae phosphating ferrei fistulae uniformes sunt coloris, altae constantiae, et bonae rubigo resistentiae.

Tubulae phosphatae ferro hydraulicae late in systematibus hydraulicis, machinis et constructionibus vehiculis constructis adhibiti sunt.

Specification

| Standard | DIN2391 DIN1630 EN10305 DIN2445 JIS SAE J524 |

| Gradus | ST35/E235 ST37.4 ST45/E255 ST52/E355 |

| Delivery Condition | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) |

| Magnitudo | OD:4 ad 219mm Crassitudo 0.5-35mm, Longitudo: 3m,5.8,6 vel secundum exigentias |

| perago | Superficies Galvanized (Sliver/Yellow/Colorful) Zinc coating of 8-12um |

| Applicationem | Hydraulic System;Car/bus;constructione vehiculum |

| Tempus adferendi | A.3 dies si hoc bonum est, stirps bona est. B. circiter XXX dies secundum quantitatem |

| HYDRAULIC PRECSIO FERRUM TUBES IN STOCK | ||||||||||

| OD | Crassitudo (mm) | |||||||||

| mm |

| |||||||||

| 4 | 4*1 |

|

|

|

|

|

|

|

|

|

| 6 | 6*1 | 6*1.5 | 6*2 |

|

|

|

|

|

|

|

| 8 | 8*1 | 8*1.5 | 8*2 |

|

|

|

|

|

|

|

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 |

|

|

|

|

|

|

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 |

|

|

|

|

|

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 |

|

|

|

|

|

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 |

|

|

|

|

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 |

|

|

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 |

|

|

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 |

|

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 |

|

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 |

|

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 |

|

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 |

| 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 |

| 34 |

| 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 |

| 35 |

| 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 |

| 38 |

|

| 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 |

| 40 |

|

| 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 |

| 42 |

|

| 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 |

| 45 |

|

| 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 |

| 46 |

|

| 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 |

| 48 |

|

| 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 |

| 50 |

|

| 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 |

| 54 |

|

|

| 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 |

| 60 |

|

|

| 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 |

| 65 |

|

|

|

| 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 |

| 75 |

|

|

|

|

| 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 |

| 76 |

|

|

|

|

|

| 76*4 | 76*4.5 | 76*5 | 76*6 |

| 89 |

|

|

|

|

|

|

|

|

| 89*6 |

| Nota: Possemus alias magnitudinum magnitudines producere sicut postulationes tuas.Superficies Treatment: Bright, Galvanized, Phosphated etc. | ||||||||||

Compositio chemica

| Steel Gradus | C | Si | Mn | P | S | Al | |

| Nomen | Nec. | max | max | max | max | max | max |

| E215 | 1.0212 | 0.1 | 0.05 | 0.7 | 0.024 | 0.014 | 0.024 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.2 | 0.024 | 0.014 | - |

| E355 | 1.058 | 0.22 | 0.55 | 1.6 | 0.024 | 0.014 | - |

| ST35 | 1.0308 | 0.17 | 0.35 | 0.4(min) | 0.024 | 0.024 | - |

| ST45 | 1.0408 | 0.21 | 0.35 | 0.4(min) | 0.024 | 0.024 | - |

| ST52 | 1.058 | 0.22 | 0.55 | 1.6 | 0.024 | 0.024 | - |

Mechanica proprietatibus

| Steel Gradus | Fortitudo cede (Mpa) | Distrahens fortitudo (Mpa) | Prolongatio% | |

| Nomen | Nec. | ReH (min) | Rm(min) | A(min) |

| E215 | 1.0212 | 215 | 290 ad 430 | 30 |

| E235 | 1.0308 | 235 | 340 ad 480 | 25 |

| E355 | 1.058 | 355 | 490 ad 630 | 22 |

| ST35 | 1.0308 | 235 | 340 ad 480 | 25 |

| ST45 | 1.0408 | 255 | 440 ad 570 | 21 |

| ST52 | 1.058 | 355 | 490 ad 630 | 22 |

tolerantia

| OD | Tolerantia licita | Special Tolerantia | ||

|

| GB/T3639 | DIN2391 | OD | WT |

| 4mm-20mm | ±0.10mm | ±0.08mm | ±0.05mm | ±0.05mm |

| 20mm-30mm | ±0.10mm | ±0.08mm | ±0.08mm | ±0.08mm |

| 31mm-40mm | ±0.15mm | ±0.15mm | ±0.10mm | ±0.08mm |

| 41mm-60mm | ±0.20mm | ±0.20mm | ±0.15mm | ±0.15mm |

| 61mm-80mm | ±0.30mm | ±0.30mm | ±0.20mm | ±0.20mm |

| 81mm-120mm | ±0.45mm | ±0.45mm | ±0.30mm | ±0.30mm |

Delivery Condition

| Designatio | Symbolum | Descriptio |

| Frigus complevit (difficile) | BK(+C) | Tubuli caloris curationem non subeunt secundum extremum frigidum formantem et sic deformatio magis resistentia |

| Frigus complevit (Soft) | BKW | Curatio caloris extremum sequitur frigus attractum deformatio limitata.Aptus processus ulterior permittit quendam gradum formandi frigoris (exempli deflexio, expansio) |

| (+LC) | ||

| Frigidus complevit et accentus, sublevetur | BKS(+SR) | Curatio caloris applicata est post extremum frigidum processum formantem.Subiectis congruis condicionibus processui, incrementa residua extollit quae involvit, dat et formare et machinere aliquo modo. |

| Annealed | GBK(+A) | Ultimum processus frigidum formans sequitur furnum in atmosphaera moderata. |

| Normalised | NBK(+N) | Ultimum frigus processus formandi sequitur furnum super punctum transmutationis superioris in atmosphaera temperata. |

Quality Assurance

1. Strict secundum DIN2391/EN10305 vel alia signa.

2. Sample: Sample gratis test.

3. Expertus: Sal imbre test/test tensile / Eddy current / Chemical compositio test secundum clientium petitionem

4. Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

Applicationem