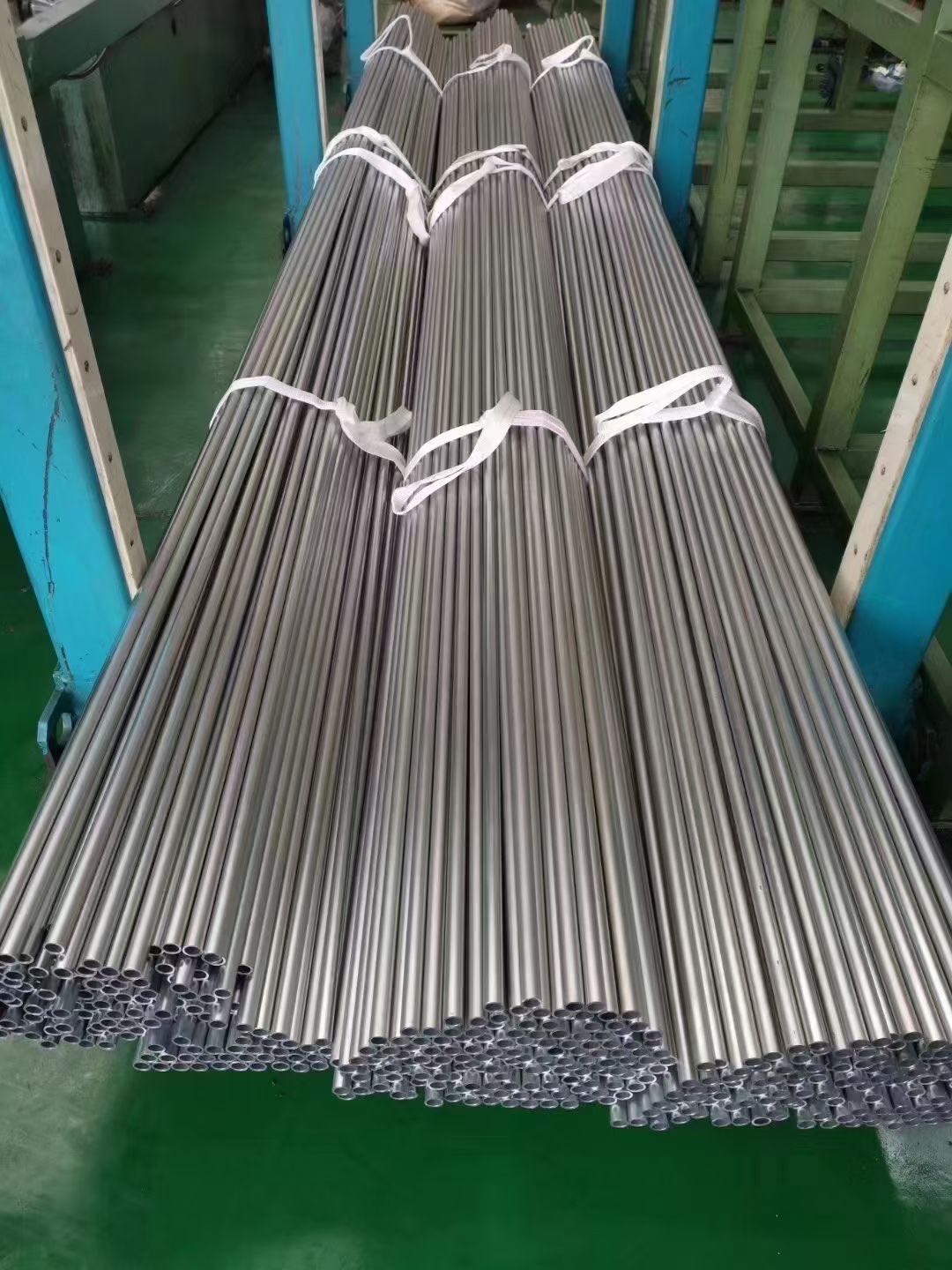

STKM11A STKM14B tubi ferrei ad currus

Specification

STKM11A gradus chalybis est ad fistulas carbonis in structuras mechanicas adhibitas, ex norma JIS G3445 orta, et gradus Iaponicae est.STKM11A tibia ferrea gradus, materia aequivalens SPHC, σ B ≥ 290MPa;CARBONES FERRUM pro STKM structurarum mechanicarum;

Notam SPHC originaliter torris germanica erat et etiam in Iaponia adhibita est.Postea a mola chalybe domestico Baosteel introducta est, laminis ferreis volventibus (quae SPCC respondentibus respondentibus) caldariis volventibus, aequivalens laminis calidis 10 # et 15 # ferro in vexillum nationalis GB699 introductum (National Standard for High Quality. Carbon structuralis Steel), cum contentus carbonis ambitus circa 0,1% -0.15%

Superficiem treatment:

1.Bared

2.Black pingitur (varnish coating)

3.Galvanized

4.Oiled

5. Secundum clientes.

JIS STKM11A~18C/DIN ST52/ASTM A106, subtilitas et asperitas superficialis frigoris, praecisio fistulae ferreae cum diametris interioribus et exterioribus meliores sunt tibiis calidis revolutis.Specificationes nativus ad superiora requisita ad vires distrahendas, vires, elongationes, etc.Frigidam praecisionem fistulae ferri cum diametris interioribus et exterioribus ad cylindros pneumaticos adhiberi possunt;Oleum pressum cylindricum;Motorcycle et bicyclus concussus absorbabilis;Aeris conditioner condenser;Motivum secundum locum ante furcam et post bipennem;Brachium mechanicum;Globus granulosus redivivus;Exhaurit;Utrem machinae flante;Apparatus adtritio;Jack;Arator;Rollerus ad imprimendum machinas, etc.

JIS G3445 Praecisio fistulae chalybeae maxime adhibentur in partibus machinis automobile et praecisione carros et cylindrici.pressionis utendi, ac etiam ad transportandum vaporem, aquam, fistulam gasi lineas.

Compositio chemica

| Gradus | Designatio | Unitas (%) | ||||||

| C | Si | Mn | P | S | Nb vel V * | |||

| Gradus 11 | A | STKM 11A | 0.12 max. | 0.35 max. | 0.60 max. | 0.040 max. | 0.040 max. | - |

| Gradus 12 | A | STKM 12A | 0.20 max. | 0.35 max. | 0.6 max. | 0.04 max. | 0.04 max. |

|

| B | STKM 12B | |||||||

| C | STKM 12C | |||||||

| Gradus 13 | A | STKM 13A | 0.25 max. | 0.35 max. | 0.30~0.90 | 0.040 max. | 0.040 max. | - |

| B | STKM 13B | |||||||

| C | STKM 13C | |||||||

| Gradus 14 | A | STKM 14A | 0.30 max. | 0.35 max. | 0.30~1.00 | 0.040 max. | 0.040 max. | - |

| B | STKM 14B | |||||||

| C | STKM 14C | |||||||

| Gradus 15 | A | STKM 15A | 0.25~0.35 | 0.35 max. | 0.30~1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 15C | |||||||

| Gradus 16 | A | STKM 16A | 0.35~0.45 | 0.40 max. | 0.40~1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 16C | |||||||

| Gradus 17 | A | STKM 17A | 0.45~0.55 | 0.40 max. | 0.40~1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 17C | |||||||

| Gradus 18 | A | STKM 18A | 0.18 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| B | STKM 18B | |||||||

| C | STKM 18C | |||||||

| Gradus 19 | A | STKM 19A | 0.25 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| C | STKM 19C | |||||||

| Gradus 20 | A | STKM 20A | 0.25 max. | 0.55 max. | 1.60 max. | 0.040 max. | 0.040 max. | 0.15 max |

Mechanica Properties

| Steel Gradus | Fortitudo cede (Mpa) | Distrahens fortitudo (Mpa) | Prolongatio% | |

| Nomen | Nec. | ReH (min) | Rm(min) | A(min) |

| STKM 11A |

| _ | 290 | 35 |

| STKM 12A |

| 175 | 340 | 35 |

| STKM 12B |

| 275 | 390 | 25 |

| STKM 12C |

| 355 | 4700 | 20 |

| STKM13A |

| 215 | 370 | 30 |

| STKM 11B |

| 305 | 440 | 20 |

| STKM11C |

| 380 | 510 | 15 |

tolerantia

| MENSURA | Tolerantia licita | Special Tolerantia | ||

| OD | WT | OD | WT | |

| 4mm-20mm | ±0.25mm | <3mm ±0.3mm;

≥3mm ±10%

| ±0.05mm | ±0.05mm |

| 20mm-30mm | ±0.25mm | ±0.08mm | ±0.08mm | |

| 31mm-40mm | ±0.25mm | ±0.10mm | ±0.08mm | |

| 41mm-49mm | ±0.25mm | ±0.15mm | ±0.15mm | |

| 50mm-80mm | ±0.5% | ±0.20mm | ±0.20mm | |

| 81mm-120mm | ±0.5% | ±0.30mm | ±0.30mm | |

qualitas certitudine

1. Strict iuxta JIS G3445 Latin vel alia signa.

2. Sample: Sample gratis test.

3. Expertus: Sal imbre test/test tensile / Eddy current / Chemical compositio test secundum clientium petitionem

4. Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

Confirma inspectionem productorum in unaquaque scaena productionis, instrumentis perfectis probatis instructum: probatio vena non perniciosa, alta pressionis resistentia, machina probatio, machina machinalis tensilis universalis, inclinatio adulatione, machina probatio, munditia analystor, elementum metallum analysr, etc. Conveniant proprietatibus mechanicis productorum, processus effectus test, validam cautionem pro idoneis products praebent.