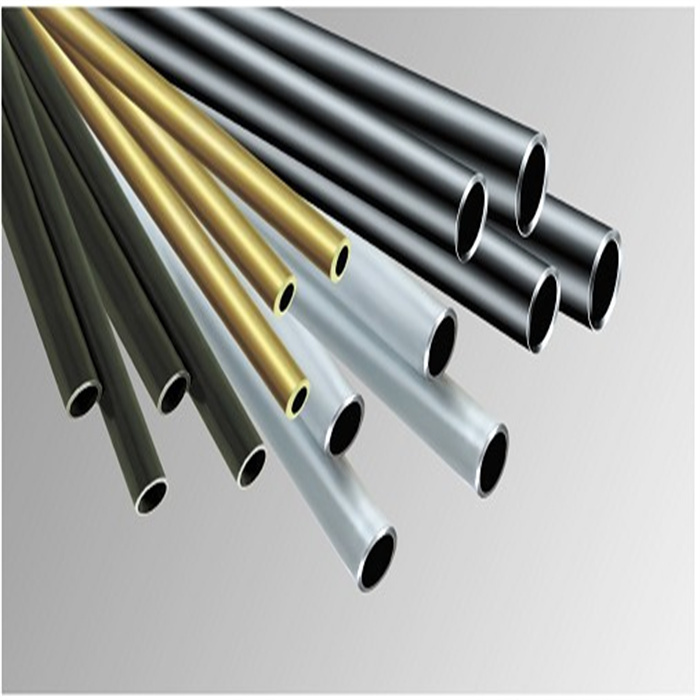

ASTM A106 A53 Gr.B A336 API 5L Seamless Steel Pipe Galvanized/Stainless/Ms Alloy Large Diameter Creber Wall Sch40 Sch80 Seamless Liquor Fire Boiler tube Pipe

amplificationem commendamus et novas solutiones in foro fere quotannis inducimus pro ASTM A106 A53 Gr.B A336 API 5L Seamless Steel Pipe Galvanized/Stainless/Ms Alloy Large Diameter Creber Wall Sch40 Sch80 Seamless Fluid Fire Boiler Tube Pipe, Winning customers' trust would be the gold key to our good results!Si insidiatus es in bonis nostris, quaeso sensu gratuito ut ad nostrum interreti locum accedas vel nos vocas.

Commonentes amplificationem et novas solutiones in forum inducunt fere per singulos annosGalvanized Steel Pipe, Summus materiae qualitate confidimus, perfecto consilio, praestantia servitii emptoris et auctoris pretii fiducia multorum clientium domi militiaeque conciliandae.95% producta ad mercatus transmarinas exportantur.

Product Detail

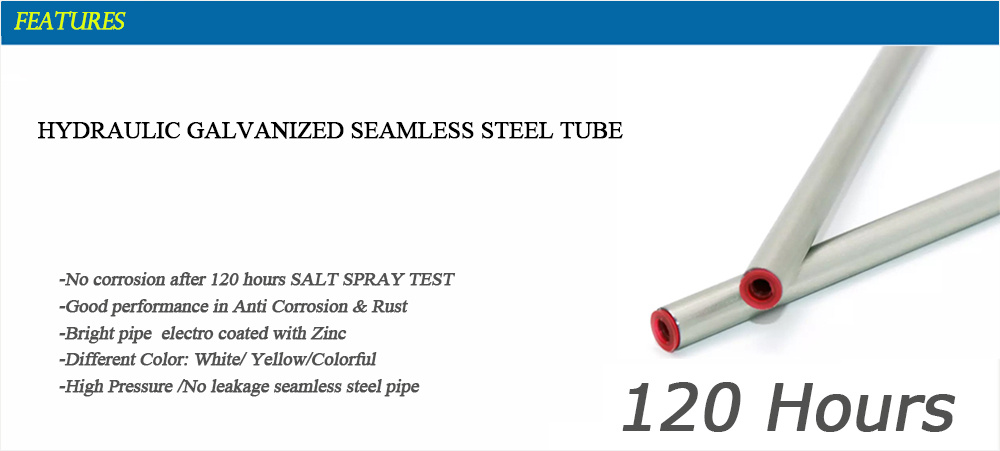

DIN2391 High Pressura hydraulica Galvanized Ferro Tubing nascitur fundamento DIN 2391-C.In systematis hydraulicis, machinae instrumentis, autocinetis, navibus, machinarum et vehiculis constructis, in usu est.Tubus hydraulicus galvanizatus inconsutilem chalybem magna subtilitate habet multas utilitates: nulla corrosio post 120 horas SAL RAMO TESTO;Bonus effectus in Anti Corrosion & Rust;Fistula electrici nitida cum zinco obducta;Color diversus: Albus / Flavus / LAETUS;Princeps Pressura / Nulla lacus seamless tibiam ferro.

Specification

| Standard | DIN2391 DIN1630 EN10305 DIN2445 JIS SAE J524 |

| Gradus | ST35/E235 ST37.4 ST45/E255 ST52/E355 |

| Delivery Condition | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) |

| Magnitudo | OD:4 ad 219mm Crassitudo 0.5-35mm, Longitudo: 3m,5.8,6 vel secundum exigentias |

| perago | Superficies Galvanized (Sliver/Yellow/Colorful) Zinc coating of 8-12um |

| Applicationem | Hydraulic System;Car/bus;constructione vehiculum |

| Tempus adferendi | A.3 dies si hoc bonum est, stirps bona est. B. circiter XXX dies secundum quantitatem |

| HYDRAULIC PRECSIO FERRUM TUBES IN STOCK | ||||||||||

| OD | Crassitudo (mm) | |||||||||

| mm |

| |||||||||

| 4 | 4*1 |

|

|

|

|

|

|

|

|

|

| 6 | 6*1 | 6*1.5 | 6*2 |

|

|

|

|

|

|

|

| 8 | 8*1 | 8*1.5 | 8*2 |

|

|

|

|

|

|

|

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 |

|

|

|

|

|

|

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 |

|

|

|

|

|

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 |

|

|

|

|

|

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 |

|

|

|

|

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 |

|

|

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 |

|

|

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 |

|

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 |

|

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 |

|

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 |

|

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 |

| 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 |

| 34 |

| 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 |

| 35 |

| 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 |

| 38 |

|

| 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 |

| 40 |

|

| 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 |

| 42 |

|

| 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 |

| 45 |

|

| 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 |

| 46 |

|

| 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 |

| 48 |

|

| 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 |

| 50 |

|

| 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 |

| 54 |

|

|

| 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 |

| 60 |

|

|

| 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 |

| 65 |

|

|

|

| 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 |

| 75 |

|

|

|

|

| 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 |

| 76 |

|

|

|

|

|

| 76*4 | 76*4.5 | 76*5 | 76*6 |

| 89 |

|

|

|

|

|

|

|

|

| 89*6 |

| Nota: Possemus alias magnitudinum magnitudines producere sicut postulationes tuas.Superficies Treatment: Bright, Galvanized, Phosphating etc. | ||||||||||

Compositio chemica

| Steel Gradus | C | Si | Mn | P | S | Al | |

| Nomen | Nec. | max | max | max | max | max | max |

| E215 | 1.0212 | 0.1 | 0.05 | 0.7 | 0.024 | 0.014 | 0.024 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.2 | 0.024 | 0.014 | - |

| E355 | 1.058 | 0.22 | 0.55 | 1.6 | 0.024 | 0.014 | - |

| ST35 | 1.0308 | 0.17 | 0.35 | 0.4(min) | 0.024 | 0.024 | - |

| ST45 | 1.0408 | 0.21 | 0.35 | 0.4(min) | 0.024 | 0.024 | - |

| ST52 | 1.058 | 0.22 | 0.55 | 1.6 | 0.024 | 0.024 | - |

Mechanica proprietatibus

| Steel Gradus | Fortitudo cede (Mpa) | Distrahens fortitudo (Mpa) | Prolongatio% | |

| Nomen | Nec. | ReH (min) | Rm(min) | A(min) |

| E215 | 1.0212 | 215 | 290 ad 430 | 30 |

| E235 | 1.0308 | 235 | 340 ad 480 | 25 |

| E355 | 1.058 | 355 | 490 ad 630 | 22 |

| ST35 | 1.0308 | 235 | 340 ad 480 | 25 |

| ST45 | 1.0408 | 255 | 440 ad 570 | 21 |

| ST52 | 1.058 | 355 | 490 ad 630 | 22 |

tolerantia

| OD | Tolerantia licita | Special Tolerantia | ||

|

| GB/T3639 | DIN2391 | OD | WT |

| 4mm-20mm | ±0.10mm | ±0.08mm | ±0.05mm | ±0.05mm |

| 20mm-30mm | ±0.10mm | ±0.08mm | ±0.08mm | ±0.08mm |

| 31mm-40mm | ±0.15mm | ±0.15mm | ±0.10mm | ±0.08mm |

| 41mm-60mm | ±0.20mm | ±0.20mm | ±0.15mm | ±0.15mm |

| 61mm-80mm | ±0.30mm | ±0.30mm | ±0.20mm | ±0.20mm |

| 81mm-120mm | ±0.45mm | ±0.45mm | ±0.30mm | ±0.30mm |

Delivery Condition

| Designatio | Symbolum | Descriptio |

| Frigus complevit (difficile) | BK(+C) | Tubuli caloris curationem non subeunt secundum extremum frigidum formantem et sic deformatio magis resistentia |

| Frigus complevit (Soft) | BKW | Curatio caloris extremum sequitur frigus attractum deformatio limitata.Aptus processus ulterior permittit quendam gradum formandi frigoris (exempli deflexio, expansio) |

| (+LC) | ||

| Frigidus complevit et accentus, sublevetur | BKS(+SR) | Curatio caloris applicata est post extremum frigidum processum formantem.Subiectis congruis condicionibus processui, incrementa residua extollit quae involvit, dat et formare et machinere aliquo modo. |

| Annealed | GBK(+A) | Ultimum processus frigidum formans sequitur furnum in atmosphaera moderata. |

| Normalised | NBK(+N) | Ultimum frigus processus formandi sequitur furnum super punctum transmutationis superioris in atmosphaera temperata. |

Quality Assurance

1. Strictum secundum DIN2391/EN10305 vel aliud vexillum.

2. Sample: Sample gratis test.

3. Expertus: Sal imbre test/test tensile / Eddy current / Chemical compositio test secundum clientium petitionem

4. Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

Applicationem

Product sarcina

Augendam amplificationem illustramus ac novas solutiones in forum fere quotannis inducunt pro Discount Lupum ASTM A106 A53 Gr.B A336 API 5L Seamless Steel Pipe Galvanized/Stainless/Ms Alloy Large Diameter Creber Wall Sch40 Sch80 Seamless Fluid Fire Boiler Tube Pipe, Winning customers' trust would be the gold key to our good results!Si insidiatus es in bonis nostris, quaeso sensu gratuito ut ad nostrum interreti locum accedas vel nos vocas.

Discount Lupum Sinis inconsutilem Ferro Pipe , materiarum qualitatem summae innitimur , perfecto consilio , excellenti servitii emptoris ac competitive pretium ut fiduciam multorum clientium domi forisque conciliaret .95% producta ad mercatus transmarinas exportantur.