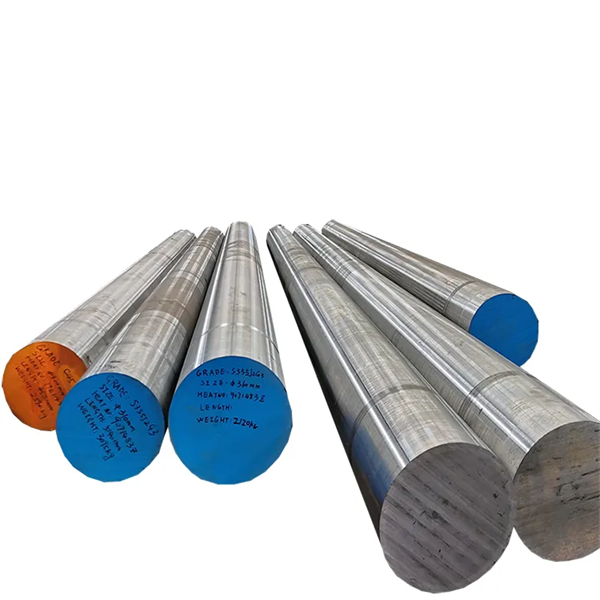

AISI 4140 SCM440 DIN 42CrMo4 1.7225 Forged Alloy Steel round Bar

Product Detail

AISI 4140 definitur ad mixturam ferri humilem, quae 1% Cr-Mo habet ad mixturam elementorum corroborandam. Comparata cum AISI 4130, superiorem carbo contentam habet cum bona statera virium, duritiem, abrasionis et ictum resistendi et caloris facultates curandi, sed pauperes in concubitu facultates indoles. AISI 4140 plerumque suppletur in condicione exstincto et temperato cum duritia 28-32HRC.

4140 Virtutem habet altam, facultatem obdurationis, duritiem, deformationem in exstinguendo.Subrepere est altum robur et patientiae robur in calidis.Usus est ad malleos fabricandos qui superiores vires requirunt et sectiones maiores exstinctas et temperatas quam 4135 ferro, ut anni magni ad tractionem motivum, anni cursus transmissionis, axes posteriores, virgas conectentes et tondeos vere oneratos.

Specification

| Product Name | AISI 4140 SCM440 DIN 42CrMo4 1.7225 Forged Alloy Steel round Bar | |

| Materia | ASTM | 4140 |

| DIN | 42crmo4 | |

| GB | 42CrMo | |

| Standard | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm ad 600mm | |

| Superficies | Niger pictus, nudum, politum, Chrome Plated | |

| Specifications | Bar rotundum | 8mm~800mm |

| Angulus bar | 3mm*20mm*20mm~12mm*800mm*800mm | |

| Quadratus talea | 4mm*4mm~100mm*100mm | |

| plana bar | 2*10mm~100*500mm | |

| Sexangulus | 4mm~800mm | |

| Conditio | Composuerunt;Hot volvitur;Frigus instructa | |

| Processus | Fornax electrica liquata ficta et annata, rotundi talea versa. | |

| Duritia: | HBS 217Max (Diversi ab aestu curationis) QT 28-32HRC | |

| UT Test | SEP 1921/84/2 C/c classis. | |

| tolerantia | Dia -0/+0~5mm, Crassitudo -0/+0~5mm, Latitudo: -0/+0~10mm. | |

| Longitudo | 2m,4m,5.8m,6m,11.8m,12m vel exigente. | |

| sarcina | Utile sarcina. | |

AISI 4140 = Grade

| Patriam | China | Iaponia | Germania | USA | Britannicus |

| Standard | GB/T 3077 | JIS G4105 | DIN (W-Nr.) EN 10250 | AISI/ASTM ASTM A29 | BS 970 |

| Gradus | 42CrMo | SCM440 | 42crmo4/1.7225 | 4140 | EN19/709M40 |

AISI 4140 ferrum chemica compositio%)

| Gradus | C | Si | Mn | P | S | Cr | Mo |

| 42CrMo | 0.38-0.45 | 0.17-0.37 | 0.5-0.80 | ≤0.035 | ≤0.035 | 0.9-1.2 | 0.15-0.25 |

| SCM440 | 0.38-0.43 | 0.15-0.35 | 0.6-0.85 | ≤0.035 | ≤0.04 | 0.9-1.2 | 0.15-0.30 |

| 42crmo4/1.7225 | 0.38-0.45 | ≤ 0.4 | 0.6-0.9 | ≤0.025 | ≤0.035 | 0.9-1.2 | 0.15-0.30 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| EN19/709M40 | 0.35-0.45 | 0.15-0.35 | 0.5-0.80 | ≤0.035 | ≤0.035 | 0.9-1.5 | 0.2-0.40 |

AISI 4140 ferro proprietatibus mechanicis

| Gradus | Tensile vi σb(MPa) | Cede vi σs (MPa) | Prolongatio δ5 (%) | De reductione (%) | Impact Precium Akv (J) | duritia |

| 4140 | ≥1080 | ≥930 | ≥12 | ≥45 | ≥63 | 28-32HRC |

Applicationem

AISI 4140 chalybs multas applicationes invenit sicut malleator ad aerospace, oleum et gas, automotivas, agriculturae et industries etc. Typical applicationes pro 4140 ferro usibus includunt: anniculos, fusos, fixtures, jigs, torques, axes, partes deportant, vectes corvus , partes colligationes, spicula, virgae, bullae, pinnae, sentinae spicula, arietes, anni circuli etc.

qualitas certitudine

1. stricte secundum Requisita

2. Sample: Sample is available.

3. Expertus: Sal imbre test/test tensile / Eddy current / Chemical compositio test secundum clientium petitionem

4. Certificate: IATF16949, ISO9001, SGS etc.

5. EN 10204 3.1 Certification