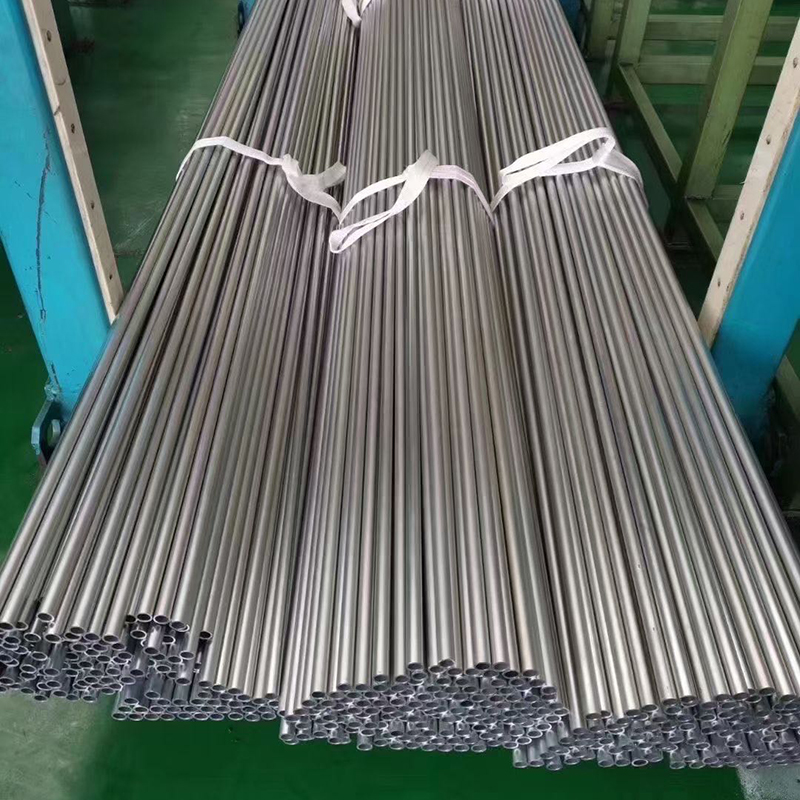

4130 30CrMo Seamless Pipe CNG Cylindri tube

Product Details

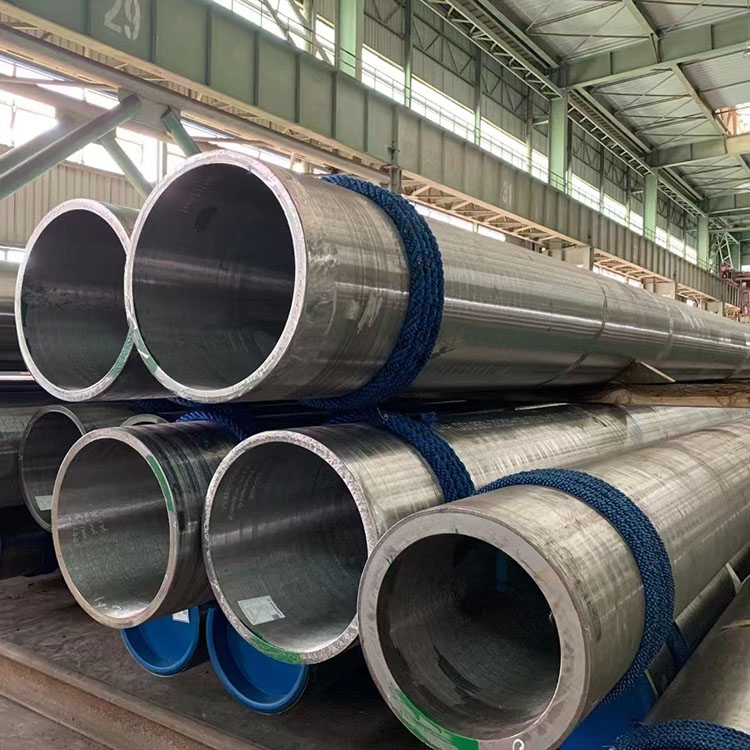

Princeps pressus gas cylindrici tubus est quasi tubus ferreus inconsutilis, vulgo tubus ferreus inconsutilis pro cylindris gasis, late in omni genere pressionis vasis altae pressionis, necnon cylindri gasi industrialis, cylindrici ignis, vehiculum CNG cylindri, vehiculum c.

Praecipua materia tubi cylindrici gasi est: 38Mn6, 30CrMo4, 30Crmo , 4130, STH11, STH12, STH21, STH22.

Princeps pressurae gasi cylindrici tubus in calidum convolutum et frigidum trahi potest.Tubus gas cylindricus involutus calidus maxime usus est ad omnia genera pressionis vasorum, cylindrorum et aliorum productorum fabricandi.Tubus cylindricus inconsutilem chalybem frigidum instructum Gas cylindricum fabricare maxime solebat ad cylindros gasi-escendos fabricandos, quae exigunt leve pondus ac parietis tenuem crassitiem, ac ferri lineri circularis vehiculi flexuosi CNG cylindrici adhibiti.

Morbi laoreet

| Item | Gut cylindrici tibia;Gut cylindrici tube |

| Standard | GB18248-2000, ASTMA335, A369, A213, A209, A250, GB5310, GB6479, GB9948, JISG3462, Etc. |

| Gradus | 4130/30CrMo,34CrMo4,30Mn2V,35CrMo,37Mn,16Mn,etc |

| Extra diametri | 40-914.4mm |

| murum crassitudine | 4mm-50mm |

| Longitudo | 5.8m, 6m, vel exigente. |

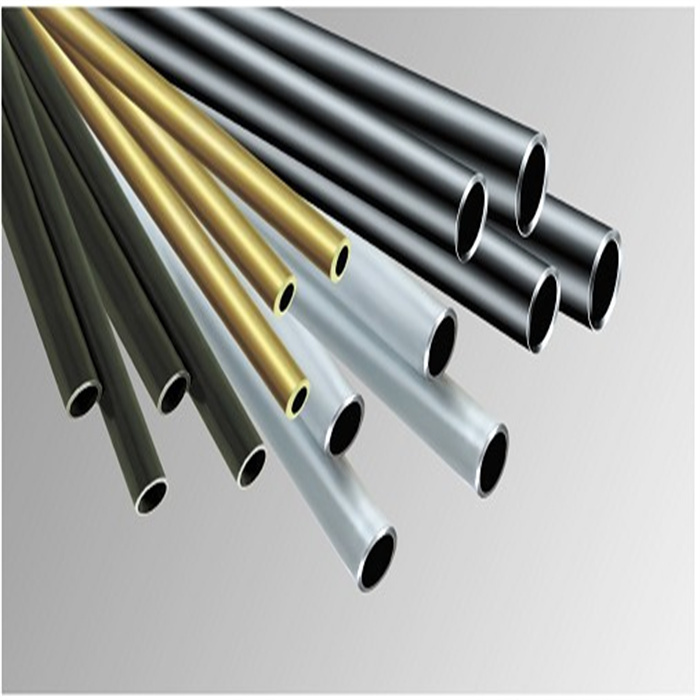

| Superficies | molendinum, varnished, nigrum linitum, NACE, Galvanized ,PE,HDPE,3PE,etc. |

| Export to | Irania, Dubai, India, Singapore, USA, UK, Indonesia, Korea, Viet Nam, Hollandia, Arabia Saudiana, Ucraina, Hibernia, Canada, Ucraina, Cuvaitum, Oman, Canada, Russia, Mexico, Peru, Chile, etc. |

| Applicationem | tubus cylindricus gasi applicat ad petroleum, industriam chemicam, vim electricam, boiler, caliditatem repugnantem, temperatura humilis resistens, corrosio resistens.Magnitudo can fiat secundum clientes requisita. |

tolerances dimensiva

Foris diametri tolerantia: +/- 1%

Crassitudinem parietis tolerantia : +30 / -0%

Tolerantia in eccentricitate : 20 max %

Tolerantia longitudinis : +30/-0 mm

Commoda nostra

1.HengYang vel TPCO qualitas specialis chalybis et eius altitudinis puritas ferri.

2. eiusque parietis crassitudo uniformitas et praecisio alta, qualitas levis, fructibus et frugibus valde altus, item cylindri fabricarum concursus facilior;

3. Fistula cylindrica producere potuimus diametrum 40~ 944.4mm, crassitudinem parietis minimi 3,5 mm;

4. Sicut determinatio conventionalis gasorum cylindrorum, tempus partus velocius est.

Variis generibus carbonis fistulae / tibiae obviam necessitates tuas

| Materia | API SPEC 5L | A25, A25A, B, X42, X46, X52, X56, X60, X65, X70, X80, X90, X100. | |

| ASTM A53/ASME SA53 | Gradus A, Gradus B; | ||

| ASTM A106/ASME SA106 | Gradus A, Gradus B, Gradus C | ||

| ASTM A210/ASME SA210 | Gradus A-1, Gradus C | ||

| ASTM A500/ASME SA500 | Gradus A, Gradus B, Gradus C, Gradus D | ||

| ASTM A501/ASME SA501 | Gradus A, Gradus B | ||

| ASTM A556/ASME SA556 | Gradus A2, B2, C2 | ||

| BS 3059 | 320, 360, 440, 620-460, 629-590, 762; | ||

| EN 10216-1&2 | P195, P235, P265 | ||

| EN10297-2 | E235, E275, E315, E355a, E470, C22E, C35E, C45E | ||

| EN10210-1 | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H | ||

| DIN 1629 | st37.0, st44.0, st52.0 | ||

| DIN 1630 | st37.4, st44.4, st52.4 | ||

| DIN 2391 | st35, st45, st52 | ||

| DIN 17175 | st35.8, st45.8 | ||

| JIS G3429 | STH11, STH 12 | ||

| JIS G3444 | STK290, STK400, STK500, STK490, STK540 | ||

| JIS G3454 | STPG370, STPG410 | ||

| JIS G3455 | STS370, STS410, STS480 | ||

| JIS G3456 | STPT370, STPT410, STPT480 | ||

| JIS G3460 | STPL380 | ||

| JIS G3461 | STB340, STB410, STB510 | ||

| JIS G3464 | STBL380 | ||

| JIS G3475 | STKN400W, STKN400B, STKN490B | ||

| Magnitudo | OD:6-2500mm WT:0.9-120mm Longitudo: 5.8m, 6m, 11.8m, 12m, vel sicut requiritur. | ||

| Ars | I) Hot Rolled | sarcina | I) Import vexillum sarcina |

| II) frigidum tracta | II) arca lignea bundled | ||

| III) frigidum Rolled | III) causa pro omnibus onerariis seu require | ||

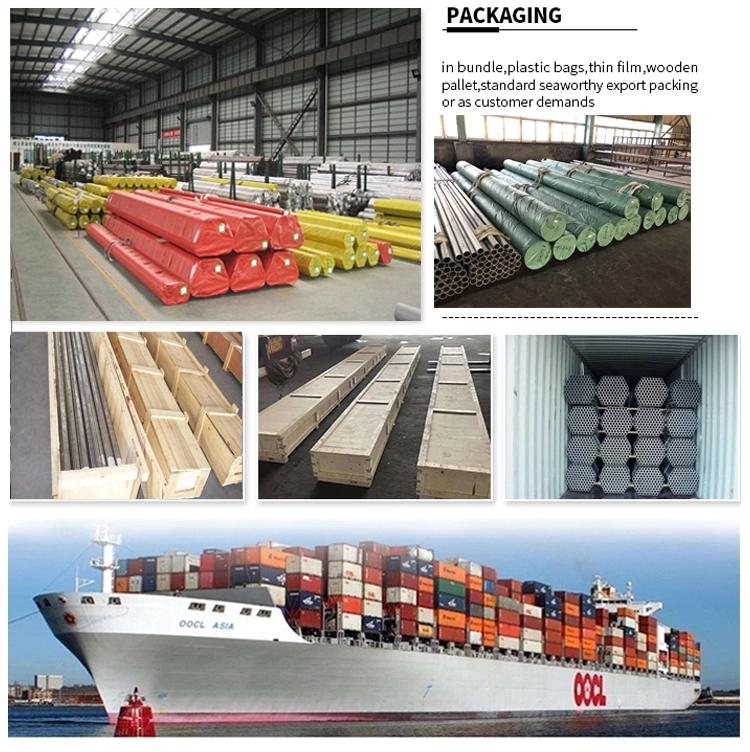

Shipping&Package